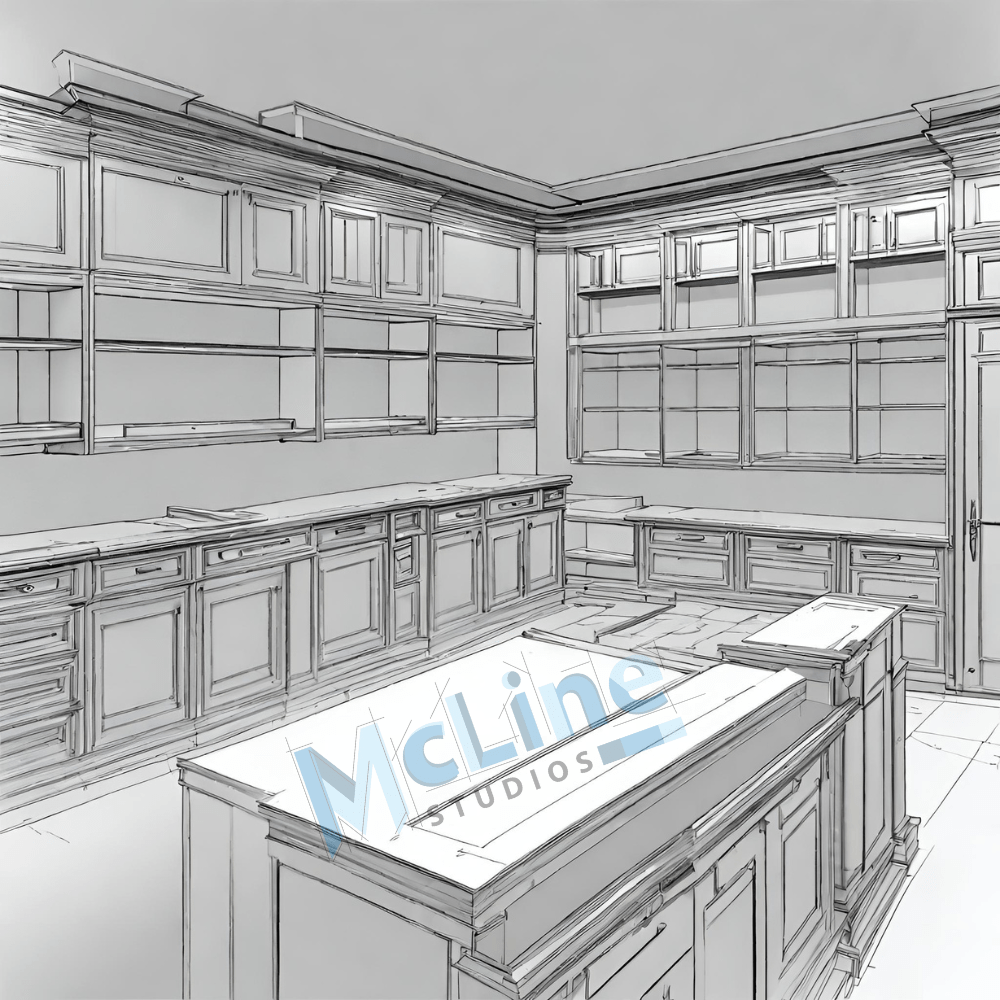

Millwork shop drawings are detailed plans and diagrams that outline the specifications for custom millwork projects. These drawings serve as a blueprint for craftsmen and carpenters, providing essential information on dimensions, materials, finishes, and assembly instructions.

Millwork shop drawings are crucial in ensuring precision and accuracy in the manufacturing process of custom millwork items such as cabinets, doors, windows, and trim. By following these drawings meticulously, craftsmen can bring the designer’s vision to life with precision and attention to detail. In essence, millwork shop drawings are the backbone of successful millwork projects.

Understanding Millwork Shop Drawing

Millwork shop drawings are detailed plans or blueprints that provide specific instructions for the fabrication and installation of custom millwork components. These drawings are essential in the woodworking and construction industries as they serve as a roadmap for craftsmen to follow when creating intricate millwork pieces such as cabinets, doors, windows, and moldings.

Typically created by experienced drafters or CAD technicians, millwork shop drawings include precise measurements, material specifications, joinery details, and assembly instructions. They help ensure that each component is accurately manufactured to meet the design requirements and fit seamlessly within the overall architectural space.

By translating design concepts into technical drawings, millwork shop drawings facilitate clear communication between designers, architects, contractors, and fabricators. They play a crucial role in streamlining the production process, minimizing errors, and ensuring the quality of the final product. In essence, millwork shop drawings are vital in bringing custom woodworking projects to life with precision and accuracy.

The Process of Millwork Shop Drawing

Millwork shop drawing plays a crucial role in the construction and fabrication process of millwork items, such as cabinets, doors, and trim. These detailed drawings serve as a blueprint for millwork manufacturers, contractors, and installers, providing essential information to ensure accuracy and quality in the final product.

The process begins with gathering specifications and requirements from architects, designers, or clients. Based on these inputs, skilled drafters create shop drawings using specialized software like AutoCAD or Revit. These drawings include precise measurements, material specifications, joinery details, and other relevant information.

Once completed, the shop drawings undergo review and approval by various stakeholders, including architects, engineers, and clients. This collaborative process ensures that the drawings accurately reflect the intended design and functionality of the millwork items.

After approval, the shop drawings guide the fabrication process, serving as a reference for manufacturers and craftsmen. They provide step-by-step instructions for cutting, shaping, and assembling the materials, helping to streamline production and minimize errors.

Ultimately, millwork shop drawings are a vital communication tool throughout the construction process, facilitating coordination between designers, manufacturers, and installers to achieve the desired outcome efficiently and accurately.

Types of Millwork Shop Drawing

Millwork shop drawings encompass various types, each serving a specific purpose in the construction and fabrication process. Here are some common types:

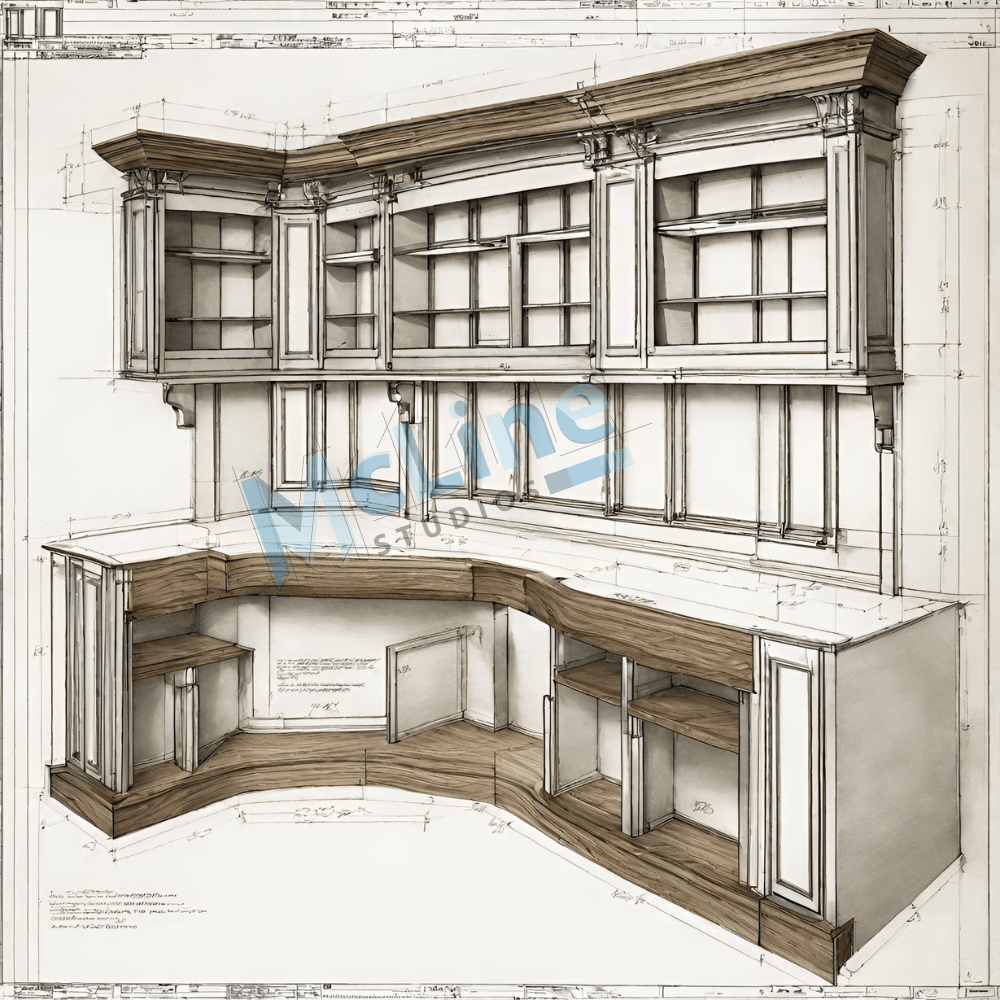

1. Elevation Drawings: These drawings provide a vertical view of millwork items, showcasing their appearance, dimensions, and design details. Elevation drawings are essential for visualizing how the finished product will look within a space.

2. Plan Drawings: Plan drawings offer a horizontal view of millwork items, illustrating their layout and spatial arrangement within a room or building. These drawings help ensure proper placement and integration with other architectural elements.

3. Detail Drawings: Detail drawings focus on specific components or sections of millwork items, providing close-up views and annotations to highlight intricate features, joinery methods, and assembly instructions.

4. Section Drawings: Section drawings offer a cut-away view of millwork items, revealing their internal structure and construction details. These drawings aid in understanding how different parts fit together and how materials are assembled.

5. Assembly Drawings: Assembly drawings depict the step-by-step process of constructing millwork items, guiding manufacturers and installers through the fabrication and installation process. These drawings ensure that all components are correctly assembled for optimal functionality and durability.

By utilizing these various types of millwork shop drawings, architects, designers, manufacturers, and contractors can effectively communicate design intent, coordinate construction activities, and achieve the desired outcome with precision and efficiency.

Conclusion

In conclusion, millwork shop drawings are indispensable tools in the construction and fabrication industry, facilitating communication, coordination, and precision throughout the design and production process. By encompassing various types such as elevation, plan, detail, section, and assembly drawings, these documents provide a comprehensive guide for architects, designers, manufacturers, and installers.

For exemplary service in millwork shop drawing and related architectural services, consider partnering with Mcline Studios. With their expertise and dedication to delivering high-quality solutions tailored to clients’ needs, Mcline Studios stands out as a reliable partner in bringing architectural visions to life.

Whether it’s creating detailed shop drawings or providing comprehensive architectural support, Mcline Studios is committed to excellence and client satisfaction, making it a valuable asset in any construction project.