Nuts and bolts are among the most basic yet essential components in the world of engineering, manufacturing, and construction. These simple fasteners, often overlooked, hold the structures and machines that define our modern world together. Their evolution mirrors the technological advancements of human civilization, reflecting the shifts in materials, manufacturing techniques, and industrial needs. This essay delves into the history of nuts and bolts – tokohasil, tracing their origins, development, and significance throughout the ages.

Early Fastening Methods

The concept of fastening objects together predates recorded history. Early humans used simple methods such as tying, pegging, or wedging to join materials. These techniques, although primitive, were sufficient for the needs of early societies. However, as human technology advanced, the limitations of these methods became apparent, particularly when working with more complex structures or machinery.

One of the earliest examples of mechanical fastening is seen in ancient Egyptian woodworking. The Egyptians used wooden dowels to fasten pieces of furniture, and they employed mortise and tenon joints secured with pegs. Although these techniques did not involve screws or bolts, they laid the groundwork for more sophisticated fastening methods.

The Invention of the Screw

The screw, which is the precursor to the modern bolt, has its origins in ancient Greece. The Greek mathematician Archytas of Tarentum, a contemporary of Plato, is often credited with inventing the screw around the 4th century BCE. These early screws were typically made of wood and were used primarily in presses for wine, olive oil, and other agricultural products. The design was simple—a threaded shaft that could be turned to move objects or exert pressure.

In the following centuries, the Romans refined the screw’s design, introducing metal screws made of bronze or iron. These screws were used in devices such as water pumps and presses. However, the use of screws remained limited due to the difficulty of manufacturing precise threads by hand. The labor-intensive process made screws and, by extension, bolts rare and expensive.

The Industrial Revolution: A Turning Point

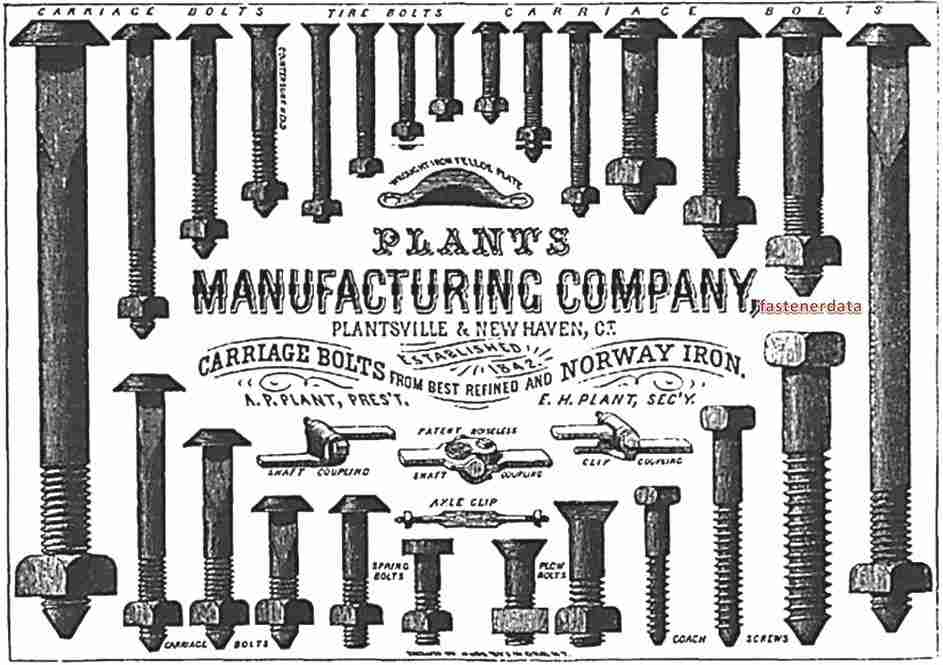

The true proliferation of nuts and bolts began with the Industrial Revolution in the late 18th and early 19th centuries. This period marked a significant leap in manufacturing capabilities, driven by advancements in machinery, metallurgy, and production techniques.

In 1760, the invention of the screw-cutting lathe by Jesse Ramsden revolutionized the production of screws and bolts. This machine allowed for the precise cutting of threads, making it possible to mass-produce screws and bolts with uniform dimensions. The screw-cutting lathe, combined with the development of high-quality steel, made these fasteners more affordable and reliable.

The Industrial Revolution also saw the standardization of threads, which was a critical step in the widespread adoption of nuts and bolts. Prior to this, screws and bolts were often custom-made for specific applications, leading to compatibility issues. In 1841, British engineer Joseph Whitworth introduced a standardized thread system known as the Whitworth thread, which became the first national standard for screw threads. This standardization allowed nuts and bolts to be interchangeable, greatly simplifying manufacturing and repair processes.

Evolution and Modernization

As industries evolved, so did the nuts and bolts that held them together. The 19th and 20th centuries saw the development of new materials and coatings to improve the performance and durability of fasteners. Steel remained the dominant material, but innovations such as stainless steel, which is resistant to corrosion, expanded the applications of nuts and bolts in environments where rust and wear were concerns.

The mid-20th century introduced the concept of high-strength bolts, designed to withstand greater forces in structural applications. These bolts are often used in construction, where they secure steel beams in skyscrapers, bridges, and other critical infrastructure. The development of torque-controlled tightening methods during this period ensured that bolts could be tightened to the precise tension required, further enhancing their reliability in critical applications.

In addition to structural advancements, the 20th century also saw improvements in bolt head design. The introduction of hexagonal heads provided better grip and made it easier to apply torque with wrenches, leading to more secure and consistent fastening. Meanwhile, the development of self-locking nuts, such as the Nyloc nut, improved safety by reducing the risk of loosening due to vibration.

The Digital Age and Beyond

The digital age has brought about further advancements in the design and manufacturing of nuts and bolts. Computer-aided design (CAD) and computer-aided manufacturing (CAM) have enabled engineers to create fasteners with unprecedented precision. Furthermore, the rise of 3D printing technology has the potential to revolutionize the production of customized nuts and bolts, allowing for rapid prototyping and on-demand manufacturing.

Modern industries continue to push the boundaries of what nuts and bolts can achieve. For instance, aerospace and automotive industries require fasteners that are not only strong but also lightweight. This demand has led to the development of advanced materials such as titanium and composites, which offer high strength-to-weight ratios. Additionally, smart bolts equipped with sensors are being developed to monitor the tension and integrity of critical fasteners in real-time, providing an added layer of safety.

Conclusion

The history of nuts and bolts – baut & mur: is a testament to human ingenuity and the relentless pursuit of innovation. From the simple wooden screws of ancient Greece to the high-tech fasteners of the modern age, nuts and bolts have played a crucial role in the development of technology and industry. Their evolution reflects broader technological trends, from the mechanization of production to the standardization of parts, and now to the era of digital manufacturing. As technology continues to advance, so too will the nuts and bolts that hold our world together, ensuring that they remain a cornerstone of engineering and construction for generations to come.