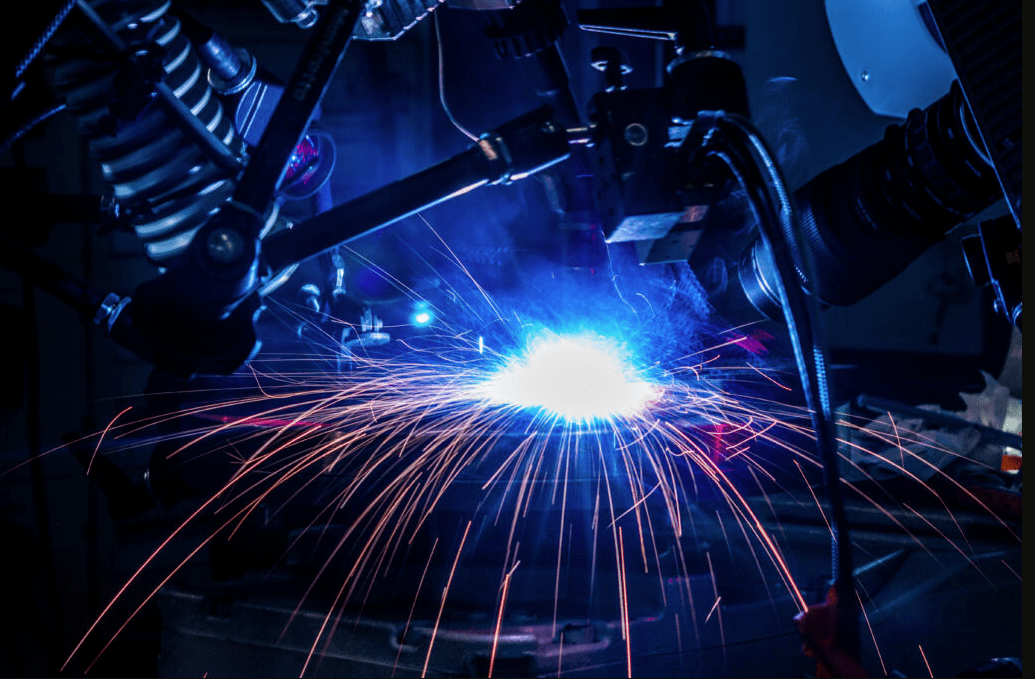

Using welding cameras for real-time visual monitoring helps oversee the ongoing process to achieve the best possible results and standardize common processes and other relevant methods. There are many ways to ensure accurate functioning and increase sales through the use of welding monitoring cameras. There are various strategies to fulfill the requirements of quality testing, all of which assist in detecting and implementing impressive strategies effectively.

Certain methods and considerations are involved in designing the cameras, as well as the underlying rationale. Welding cameras are compact and powerful, enabling them to withstand industrial settings with the utmost security. They have been introduced to ensure an accurate development process and provide security across industries, promoting a comprehensive view.

Enhance Process Understanding With High-Quality Images

This invention assists in managing visual inspection and detects any drawbacks. There are provided signals to undermine the actual purpose throughout. The less chances of coming across any issues as it helps to downtime the limitation of any production errors.

With this, there is non-destructive streamlined planning. Even in the eCommerce platform, once the orders are laced there’s a firm record if there are any customer claims. These records serve the purpose of providing information in manual fulfillment. Multiple studies are done in diverse parameters, which identify the differential dimensions of progressive methods.

You must be wondering why should we use a welding camera to secure the hazardous or any other restricted area. One of the main purposes is to help execute welding operations from a distance. Below are advantages serving the actual aspect.

- Utmost Safety

These are small cameras that allow robust features and maintain the surroundings throughout. Consistent safety precautions are served despite the circumstance or adjustable in multiple situations.

- Optimized Time

The welding is also improved with equipped features available, hence, preliminary visuals are there to examine the entire situation delegating the accuracy of dynamic approaches. with this, welders tend to keep an eye on the entire process while focusing on other aspects.

- In-Depth Inspection

Once the welding is done the cameras tend to check the surface and below-surface conditions. Managing overall outcomes, to make it acceptable across the domain. Similarly, there are multiple ways to finalize the quality turnouts.

Creating Optimal Welding Conditions With Determined Approaches

It is easier to remotely align with specific features such as a welding torch and a gap. Welding access ensures enhanced security and incorporates precautionary measures to supply real-time procedures. As a result, compact cameras improve work safety by monitoring procedures and enhancing the operator’s ergonomics. This allows the welding process to be managed without consistent pauses, ultimately promoting business advancement. Below mentioned qualities below have diverse ways to introduce new technical advancements within the welding monitoring system. Utilizing the welding camera helps in pitching the high dynamic range imagining which helps in producing clarity as well.

- Dross detection section from welds and maintaining the cooling systems.

- Revealing significant potential for protecting the surroundings and securing them from impurities keeping metal clean.

- Aligning the filler material to have a seamless process in seaming.

- Cameras help to monitor the ongoing changes and undermine the ways to shield gas.

- Confirming the accurate placement and adhering to the confirmation.

Consistent inspection and maintenance of welding equipment are essential, advancing the optimal performance throughout to manage security and other relevant purposes. Well-maintained equipment reduces the risk of breakdowns, accidents, and defects in the welding process.

Now implementing equipped and advanced approaches is simple and organized throughout. A foremost welding environment prioritizing the worker’s well-being enhances productivity and delivers superior weld quality.

Therefore, the ability to monitor the entire process also requires skills. There are diverse operative systematic approaches that involve realigning the welding process and assisting in the corrective action plan. There’s this arc weld version assisting in weld completion more rapidly and accurately. This advanced system detects the potential issues such as;

- Porosity at times enables multiple shielding gas-related disturbances.

- Sidewall fusions are commonly detected and result in incorrect welding procedures.

- Irregulates the welding surface groundings and segmentation of seam is visible.

- Due to the metal distortion, there are high chances of excessive heat or gas release.

- Wire position is essential as it helps in positioning and promoting comprehensive approaches, hence if needed cameras can detect the puddle and reduce void.

Summing Up!

Welding camera operators are essentially playing the role that empowers quality control, and process monitoring. As per expertise cameras enable specialized operation, directing to capture detailed images of the welding process, identifying defects, and adhering to standard procedures. This role requires a keen focus and uttermost information along with technical proficiency in welding aspect. if Welding Monitoring Camera buyers, it is ideal to consider the right domain and have secured purchasing.