Industrial storage tanks stand as colossal sentinels, silently holding the lifeblood of industries and playing a strategic role in the seamless functioning of diverse sectors. From petrochemicals to water treatment, these tanks serve as repositories of critical raw materials, finished products, and resources that fuel the engine of modern economies. This post delves into the strategic significance of industrial storage tanks, exploring their multifaceted roles, types, and the key considerations that make them indispensable assets for industrial operations.

The Diverse Roles of Industrial Storage Tanks

Industrial storage tanks serve as reservoirs for raw materials, whether it’s crude oil, chemicals, or liquid feedstock. Ensuring a steady and reliable supply of raw materials is crucial for maintaining production continuity and meeting market demands. After the manufacturing process, industrial storage tanks become repositories for finished products. This includes everything from refined petroleum products and chemicals to beverages and food items. Storage tanks provide a buffer, allowing for efficient distribution and responding to fluctuating market demands.

Storage tanks play a role in managing industrial waste and byproducts. Whether it’s storing wastewater for treatment or holding materials for recycling, these tanks contribute to responsible waste management practices, aligning with sustainability goals. In complex manufacturing processes, intermediate storage is often required. Industrial storage tanks act as temporary holding vessels for intermediate products, facilitating a continuous and smooth production flow.

Types of Industrial Storage Tanks

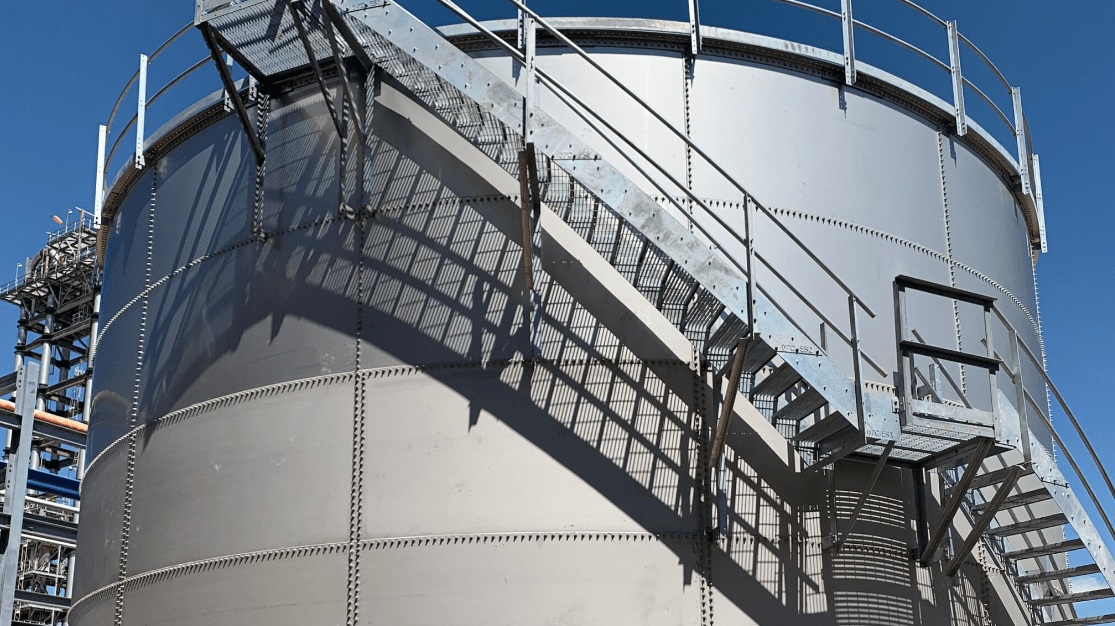

- Above-Ground Storage Tanks (ASTs):

ASTs are commonly used for storing liquids such as petroleum, chemicals, and water. They are versatile, cost-effective, and can be designed to accommodate various capacities. ASTs are prevalent in industries like oil and gas, petrochemicals, and water treatment.

- Underground Storage Tanks (USTs):

USTs are buried below the ground surface and are employed for storing substances like fuel and hazardous materials. They are space-efficient and provide added safety by being concealed. However, they require careful monitoring and maintenance to prevent leaks and environmental contamination.

- Pressure Vessels:

Pressure vessels are designed to store substances under pressure. They are widely used in industries such as chemical manufacturing, pharmaceuticals, and energy. Pressure vessels must adhere to stringent safety standards due to the potential risks associated with pressurized contents.

- Silos:

Silos are specialized storage tanks used for bulk materials such as grains, cement, and coal. They are characterized by their tall, cylindrical structure and are crucial in industries like agriculture, construction, and manufacturing.

Key Considerations in Industrial Storage Tank Design and Placement

Material Compatibility:

The choice of materials for constructing storage tanks is critical. It depends on the nature of the stored substance, considering factors such as corrosiveness, reactivity, and temperature. Common materials include steel, fiberglass, and concrete.

Safety Standards and Regulations:

Compliance with safety standards and regulations is paramount. Industrial storage tanks must adhere to industry-specific guidelines and governmental regulations to ensure the safety of both the facility and the surrounding environment.

Environmental Impact:

Preventing environmental contamination is a crucial consideration in tank design and placement. Measures such as secondary containment systems, leak detection, and spill prevention are implemented to mitigate the environmental impact of potential leaks or spills.

Capacity and Scalability:

Determining the appropriate tank capacity is essential. Industrial facilities must assess their current and future storage needs, considering factors like production growth and market demand. Scalability is crucial to accommodate changes in storage requirements.

The Strategic Significance in Industry Sectors

Oil and Gas Industry: In the oil and gas sector, storage tanks are central to the entire supply chain. From upstream operations like crude oil storage to downstream activities involving refined product storage, these tanks ensure a continuous and reliable flow of hydrocarbons.

Chemical Manufacturing: Chemical manufacturing relies heavily on specialized storage tanks for both raw materials and finished products. The diverse and often hazardous nature of chemicals necessitates precise design and adherence to safety protocols.

Water and Wastewater Treatment: Water treatment plants utilize storage tanks for various purposes, including holding raw water, storing treated water, and managing wastewater. These tanks contribute to the efficiency and resilience of water treatment processes.

Food and Beverage Industry: Storage tanks are integral to the food and beverage industry for holding ingredients, intermediate products, and finished goods. Hygiene, material compatibility, and adherence to food safety standards are paramount in this sector.

Challenges and Future Considerations

- Aging Infrastructure:

Many industrial facilities face the challenge of aging storage tank infrastructure. Upgrading and maintaining these assets to meet modern safety and environmental standards is a significant consideration.

- Cybersecurity Risks:

With the increasing integration of digital technologies, the risk of cybersecurity threats to storage tank operations has risen. Protecting critical infrastructure from cyber attacks is a growing concern that requires ongoing vigilance.

- Resilience to Extreme Events:

Climate change and the potential for extreme weather events underscore the importance of designing storage tanks with resilience in mind. This includes considerations for floods, hurricanes, earthquakes, and other natural disasters.

- Circular Economy Practices:

Embracing circular economy principles involves optimizing resource use, reducing waste, and promoting recycling. Applying these practices to industrial storage tanks includes exploring ways to repurpose materials and extend the life cycle of tanks.

Conclusion

Industrial storage tanks are not mere vessels; they are strategic assets that underpin the reliability, safety, and sustainability of industrial processes. From safeguarding raw materials to ensuring the availability of finished products, these tanks play a pivotal role in the intricate dance of modern supply chains. As industries evolve, embracing technological advancements and sustainability practices, the strategic significance of industrial storage tanks will continue to grow. Through innovation, adherence to safety standards, and a commitment to environmental stewardship, these silent giants will remain essential components in the infrastructure that fuels our economies and sustains our way of life.