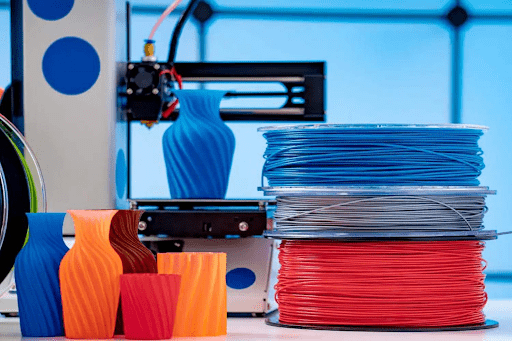

In the dynamic world of 3D printing, the filament serves as the lifeblood of the process, enabling the creation of intricate and customizable objects with precision and efficiency. In this comprehensive guide, we explore the diverse world of 3D print filaments, uncovering its types, properties, applications, and emerging trends shaping the future of additive manufacturing.

Understanding 3D Print Filament

At the heart of every 3D printing project lies the filament, a thermoplastic material that melts and extrudes through a nozzle to form layers and build three-dimensional objects layer by layer. Filaments come in various types, each offering unique properties and characteristics tailored to specific applications and requirements.

Types of 3D Print Filament

- PLA (Polylactic Acid): PLA is a biodegradable and environmentally friendly filament derived from renewable resources such as cornstarch or sugarcane. It is known for its ease of use, low odor, and vibrant color options, making it ideal for prototyping, hobbyist projects, and educational purposes.

- ABS (Acrylonitrile Butadiene Styrene): ABS is a durable and impact-resistant filament commonly used in industrial and engineering applications. It exhibits excellent strength, heat resistance, and machinability, making it suitable for functional prototypes, automotive parts, and consumer products.

- PETG (Polyethylene Terephthalate Glycol): PETG is a versatile filament known for its strength, flexibility, and chemical resistance. It offers the best of both PLA and ABS, combining ease of printing with durability and reliability. PETG is commonly used in mechanical parts, medical devices, and food containers.

- TPU (Thermoplastic Polyurethane): TPU is a flexible filament with rubber-like properties, making it suitable for applications requiring elasticity and impact resistance. It is often used in producing footwear, phone cases, and wearable devices.

- Nylon: Nylon is a strong and durable filament known for its high tensile strength, chemical resistance, and low friction properties. It is used in a wide range of industrial applications, including gears, bearings, and structural components.

Properties and Characteristics

Each type of high-quality filament for 3D printing possesses unique properties and characteristics that influence its suitability for specific applications. These properties include:

- Strength and Durability: Filaments vary in strength and durability, with some being more suitable for functional parts and prototypes requiring mechanical integrity.

- Flexibility and Elasticity: Flexible filaments offer elasticity and flexibility, allowing for the creation of bendable and stretchable objects.

- Heat Resistance: Some filaments exhibit high heat resistance, making them suitable for applications exposed to elevated temperatures.

- Chemical Resistance: Certain filaments are resistant to chemicals and solvents, making them suitable for applications requiring exposure to harsh environments.

- Printability: Filaments differ in printability, with some being easier to print with minimal warping and nozzle clogging, while others require specific printing conditions and parameters.

Applications of 3D Print Filament

The versatility of 3D printer filament enables a wide range of applications across various industries and sectors, including:

- Prototyping: Filaments are commonly used for rapid prototyping of product designs, allowing for quick iteration and validation of concepts.

- Manufacturing: Additive manufacturing with filaments enables the production of customized and low-volume parts for aerospace, automotive, and consumer goods industries.

- Education: Filaments are used in educational settings to teach students about design, engineering, and manufacturing principles through hands-on 3D printing projects.

- Healthcare: Filaments are utilized to produce medical devices, prosthetics, and anatomical models for surgical planning and training.

- Art and Design: Artists and designers leverage filaments to create sculptures, jewelry, and decorative objects with intricate details and custom designs.

By understanding the types, properties, and applications of 3D print filament, manufacturers, designers, and hobbyists can harness their full potential to bring their ideas to life. Choose a reputable source to buy 3D printing filament online in the USA!

Conclusion

In conclusion, 3D print filament is the backbone of additive manufacturing, enabling the creation of customized and functional objects across various industries. With a diverse range of filaments offering unique properties and applications, the possibilities for innovation and creativity in 3D printing are endless.