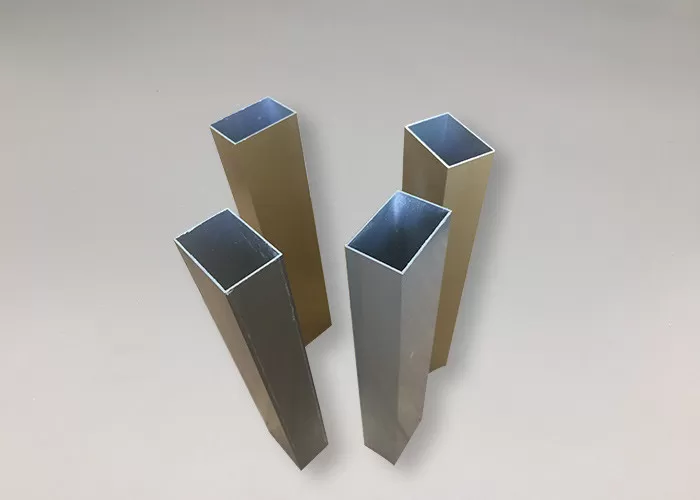

In the realm of modern manufacturing and construction, anodised aluminium sections have emerged as a game-changing solution. This process enhances the natural properties of aluminium, providing a durable and aesthetically pleasing finish that meets the demands of various industries. Anodising is an electrochemical process that forms a protective oxide layer on the surface of aluminium, significantly improving its resistance to corrosion, wear, and environmental factors. As industries increasingly prioritize sustainability, durability, and aesthetics, the importance of anodised aluminium sections cannot be overstated. This article will explore the numerous benefits of anodised aluminium sections, highlighting their significance in today’s competitive market.

1.Enhanced Corrosion Resistance

One of the most significant advantages of anodised aluminium is its exceptional corrosion resistance. The anodising process creates a thick layer of aluminium oxide that acts as a protective barrier against environmental factors such as moisture, salt, and pollutants. This enhanced resistance is particularly beneficial in industries where materials are exposed to harsh conditions, such as marine, automotive, and construction. By preventing corrosion, anodised aluminium sections extend the lifespan of products and reduce maintenance costs, making them a smart investment for manufacturers.

2. Durability and Wear Resistance

Anodised aluminium sections are not only resistant to corrosion but also exhibit remarkable durability and wear resistance. The anodic layer formed during the anodising process is significantly harder than untreated aluminium, making it more resistant to scratches, impacts, and abrasions. This characteristic is particularly valuable in applications where materials are subjected to heavy use or contact with other surfaces. As a result, anodised aluminium sections can maintain their structural integrity and aesthetic appeal over time, reducing the need for frequent replacements.

3. Aesthetic Appeal

The anodising process allows for a variety of finishes and colors, enhancing the aesthetic appeal of aluminium sections. Anodised surfaces can be dyed in a wide range of colors, providing designers and architects with the flexibility to create visually striking products that meet their design specifications. The natural metallic finish of anodised aluminium also retains its luster over time, making it an attractive choice for both interior and exterior applications. This aesthetic versatility is particularly beneficial in industries such as architecture and consumer electronics, where appearance plays a crucial role in product acceptance.

4. Low Maintenance Requirements

Anodised aluminium sections are designed for easy maintenance. The anodic layer is resistant to staining and can be easily cleaned with mild soap and water, making it ideal for applications where cleanliness is essential. Unlike painted or coated surfaces that may peel or chip over time, anodised finishes are durable and require minimal upkeep. This low maintenance requirement not only saves time and resources but also ensures that products remain in excellent condition throughout their lifecycle.

5. Improved Adhesion for Coatings and Paints

The anodised surface of aluminium sections provides an excellent base for further coatings and paints. The porous structure of the anodic layer allows for better adhesion, enhancing the durability and longevity of applied finishes. This property is particularly important in applications where additional coatings are necessary for aesthetic or functional purposes. By improving adhesion, anodised aluminium sections can accommodate a variety of finishes, ensuring that products meet specific performance and design requirements.

6. Sustainability and Recyclability

As industries increasingly focus on sustainability, anodised aluminium sections stand out as an environmentally friendly choice. Aluminium is a highly recyclable material, and the anodising process does not compromise its recyclability. In fact, anodised aluminium can be recycled without losing its inherent properties, making it a sustainable option for manufacturers. By choosing anodised aluminium sections, companies can reduce their environmental impact and contribute to a circular economy, aligning with the growing demand for eco-friendly practices.

7. Thermal and Electrical Insulation

Anodised aluminium sections offer improved thermal and electrical insulation properties. The anodic layer is a poor conductor of electricity, making anodised aluminium an ideal choice for applications that require electrical insulation. This characteristic is particularly valuable in the electronics industry, where components must be protected from electrical interference. Additionally, anodised aluminium provides thermal insulation, helping to maintain temperature stability in various applications, from building facades to heat exchangers.

8. Versatility Across Industries

The versatility of anodised aluminium sections makes them suitable for a wide range of applications across various industries. From architectural elements such as window frames and curtain walls to automotive components and consumer electronics, anodised aluminium is utilized in countless products. Its ability to meet diverse performance and aesthetic requirements has made it a preferred material for manufacturers looking to enhance their product offerings.

9. Cost-Effectiveness

While the initial cost of anodising may be higher than untreated aluminium, the long-term benefits far outweigh the investment. The durability, corrosion resistance, and low maintenance requirements of anodised aluminium sections lead to significant cost savings over time. By reducing the need for repairs, replacements, and frequent maintenance, manufacturers can achieve a higher return on investment. Additionally, the aesthetic appeal of anodised finishes can enhance product value and marketability, further contributing to cost-effectiveness.

10. Safety and Health Benefits

Anodising is a safe and environmentally friendly process that does not involve harmful chemicals or emissions. The anodic layer is chemically stable and non-toxic, making it suitable for applications in industries such as food and pharmaceuticals. By choosing anodised aluminium sections, manufacturers can ensure that their products meet health and safety standards, providing peace of mind for both producers and consumers. By selecting aluminium anodizing sections, manufacturers demonstrate their commitment to responsible manufacturing and contribute to a cleaner, healthier environment for all.

The importance of anodised aluminium sections in modern manufacturing cannot be overstated. From enhanced corrosion resistance and durability to aesthetic appeal and sustainability, anodised aluminium offers a multitude of benefits that make it a preferred choice across various industries. As manufacturers continue to prioritize quality, performance, and environmental responsibility, the adoption of anodised aluminium sections will undoubtedly play a crucial role in shaping the future of product design and development. By leveraging the advantages of anodised aluminium, companies can create innovative, high-quality products that meet the demands of today’s market while contributing to a more sustainable future.