Enter the IQT system – an innovative CVCC instrument that has been reshaping the industry landscape since its inception in 1998. Recognized as the gold standard referee test method in EN 15940, governing paraffinic fuels throughout Europe, the IQT system emerges as the epitome of reliability, precision, and cost-effectiveness. Its unparalleled features include minimal sample requirements, decreased combustion air necessities, and economically viable reference materials, setting it apart as the preferred choice. Whether you’re engaged in fuel blending or pioneering research, the IQT’s precision and accuracy are unparalleled. With a global footprint boasting over 200 installations and a staggering track record of over 100,000 test runs, the IQT system’s reputation for unwavering trustworthiness speaks volumes.

Introducing the IQT TALM Precision Package

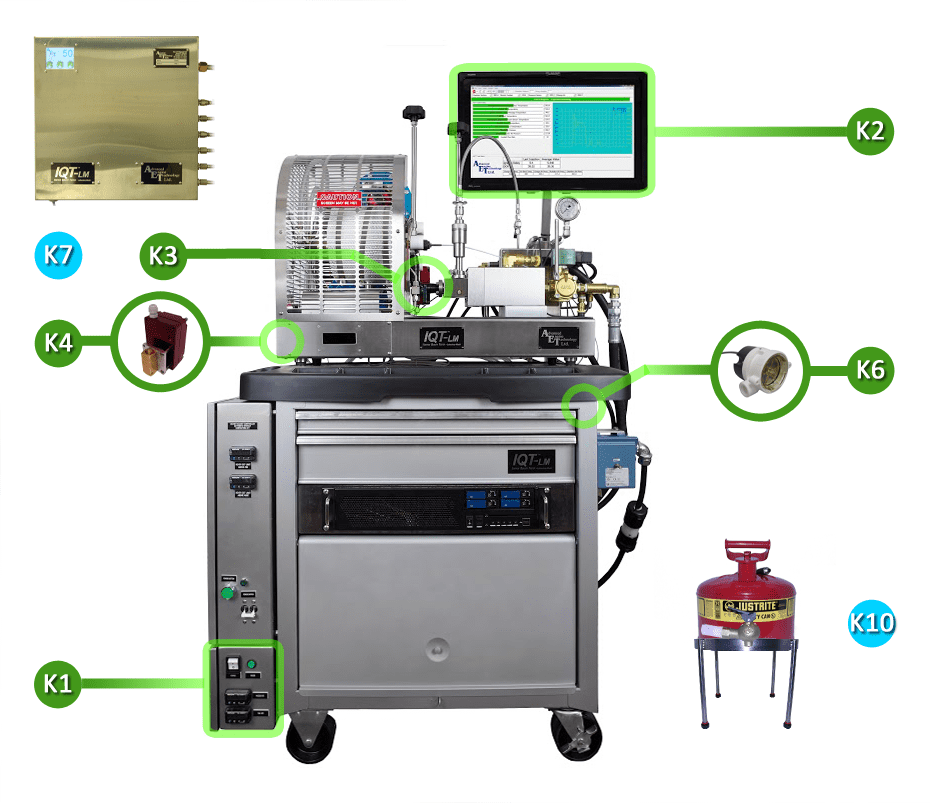

Enhance your fuel testing endeavours with the IQT TALM Precision Package, an advancement that propels the standard LM system to newfound heights. This package integrates eight essential upgrade kits, ensuring the pinnacle of automation, precision, and user-friendliness. For those seeking a holistic solution, the TALM Precision Package bundles five core TALM kits to augment precision and streamline operations.

TALM-K1: Advancing Control Cabinet

The control cabinet serves as the electronic hub for other automated components, making it an indispensable addition for kits K3 to K6 and K10.

TALM-K2: IQT System and Control Software

The IQT TALM software revolutionizes test monitoring with enhanced visibility, accessible from any corner of your lab. It simplifies calibration through automated, unattended mode testing, thereby boosting productivity and convenience.

TALM-K3: Nozzle Tip Temperature Control

Elevate IQT precision while eliminating the need for manual coolant flow adjustments with this kit (requires TALM K1 and K2 kits).

TALM-K4: Combustion Chamber Tail Temperature Control

Experience heightened IQT precision by negating the necessity for manual coolant flow adjustments in the combustion chamber tail (requires TALM-K1 and K2 kits).

TALM-K6: Electronic Coolant Flow Indicator

Bid adieu to manual coolant flow checks at the onset and conclusion of an operating period. Kit K6 provides automated digital coolant flow indication within IQT™ System Software (ISS) (requires TALM-K1 and K2 kits).

Discover More TALM Upgrade Kits

TALM-K7: Electronic Pressure Regulator Panel (optional)

Elevate automation and precision further with this panel, which governs gas stream pressures and monitors cylinder gas levels. It obviates the need for manual gas pressure adjustments, thereby enhancing precision, and provides warnings for low gas levels.

TALM-K8: Enhanced Heater Monitoring Tool (coming soon)

TALM-K9: Self-Sealing Fuel Reservoirs with Filling Cleaning Station

Augment productivity, safety, and fuel handling with self-sealing reservoirs that facilitate remote filling. Prepare samples in advance for expedited testing and heightened efficiency.

TALM-K10: Waste Fuel Container

Automate fuel level monitoring in the waste fuel container to avert spills. Receive operator alerts through the TALM-K2 graphical user interface (requires TALM-K1 and K2 kits).

Key Features Setting IQT Apart

- ASTM D6890-18 extends the testing range (31.5 to 75.1 DCN) with enhanced precision.

- Sensitive to cetane improver additives and minor fuel quality variations.

- Measures high levels of cetane improver (3000 ppm+ 2EHN) without negative carryover effects.

- Ideal for testing highly paraffinic fuels from synthesis or hydro-treatment.

- Automated, noiseless operation for seamless usability.

- Short test time (under 20 minutes) ensures heightened productivity.

- Small sample size (less than 100 mL) reduces resource consumption.

- Sturdy system with minimal operating and maintenance costs.

- Hassle-free maintenance access.

- Proven safety track record over the years.

- Trusted for testing B100 and various biodiesel fuels from diverse sources.

Frequently Asked Questions About the IQT Fully Automated Laboratory Model

What is the IQT system, and why is it significant in fuel testing?

The IQT system stands as a cutting-edge Constant Volume Combustion Chamber (CVCC) instrument, pivotal in fuel testing since 1998. Its significance lies in its role as the referee test method in EN 15940, governing paraffinic fuels in Europe, establishing it as a reliable, precise instrument with minimal operating costs.

What are the key advantages of the IQT system?

The IQT system offers benefits such as a small sample size, reduced specification combustion air, and cost-effective reference materials. Its exceptional precision makes it invaluable for fuel blending and research. With over 200 installations globally and a proven track record, it exemplifies reliability.

What is the IQT TALM Precision Package, and how does it enhance the standard IQT system?

The IQT TALM Precision Package comprises upgrade kits designed to elevate automation, precision, and user-friendliness of the standard IQT system. It includes kits like TALM-K1 (System Control Cabinet), TALM-K2 (IQT System and Control Software), and more, aimed at enhancing the testing experience.

Can I customize my IQT TALM Precision Package with specific upgrade kits?

Absolutely! The TALM Precision Package offers flexibility with eight available upgrade kits. You can select the kits that best suit your needs, or opt for the comprehensive TALM Precision Package, bundling five primary TALM kits.

How does the TALM-K7 Electronic Pressure Regulator Panel benefit IQT operators?

The TALM-K7 panel enhances automation and precision by controlling gas stream pressures and monitoring gas levels in cylinders. It eliminates manual gas pressure adjustments, ensures stable gas pressures, and alerts operators of low gas levels, preventing test interruptions.

What are the key features that distinguish the IQT system from other fuel testing instruments?

The IQT system sets itself apart with its extended testing range (31.5 to 75.1 DCN), sensitivity to cetane improver additives, capability to measure high levels of cetane improver without carryover effects, suitability for testing highly paraffinic fuels, automation, noiseless operation, short test times, small sample size, low operating costs, and proven safety track record.

Can the IQT system test biodiesel fuels, and from what sources?

Yes, the IQT system demonstrates testing capability for B100 and various biodiesel fuels from diverse sources. Its versatility and adaptability cater to a wide array of fuel types.

How can I learn more about the IQT system and its capabilities for my specific needs?

To explore the IQT system’s capabilities and discuss its alignment with your specific requirements, please reach out to our team of experts. They are eager to provide detailed insights and guidance tailored to your needs.