Introduction

In today’s fast-paced furniture and woodworking industry, craftsmanship alone isn’t enough. For businesses aiming to stay ahead, blending innovation with precision is paramount. Enter SAMACH, a company dedicated to delivering Woodworking Machine solutions tailored for intelligent furniture production. Especially notable is their expertise in Edge Banding Machine technology—an essential tool for finishing panels with flawless, durable edges. Whether you’re managing a high-volume factory or a bespoke workshop, SAMACH’s offerings promise unmatched quality, efficiency, and adaptability.

SAMACH: A Snapshot of the Brand

SAMACH positions itself as a provider of “Professional solutions for intelligent furniture”. Their portfolio spans a comprehensive lineup of machinery across multiple segments:

- Wood Based Panels Machinery: featuring equipment such as Edge Banding Machines, Panel Saws, CNC Routers, Membrane Press Machines, Painting Machines, and Sanding Machines.

- Solid Wood Machinery: including components for log processing, planing and moulding, finger-joint making, and specialized processing for chairs and doors.

- Metal Processing Machinery: covering laser cutting, press brakes, shearing, and metal sanding.

- Other Machinery: rounding out their suite for comprehensive woodworking and factory solutions.

This range demonstrates SAMACH’s understanding of modern production demands—from panel preparation to finish.

The Role of a Woodworking Machine in Modern Manufacturing

To transform raw materials into beautifully crafted pieces, workshops rely on a variety of Woodworking Machines:

- Panel Saws – For precision cutting and panel sizing.

- CNC Routers – For intricate shaping and detail work.

- Planers and Moulders – To smooth and profile surfaces.

- Drilling & Boring Machines – For accurate pre-drilled joinery positions.

- Sanding and Painting Machines – For flawless surface finish.

SAMACH offers solutions in all these categories, providing users a one-stop suite of reliable, often automated, machinery—ideal for scalable operation.

Edge Banding Machine: Transforming Panels with Polish and Durability

A linchpin in panel-based furniture manufacturing is the Edge Banding Machine. These machines are essential for:

- Protecting exposed panel edges from moisture and wear;

- Offering a visually seamless finish, enhancing aesthetics;

- Allowing quick adhesive application, trimming, and polishing—all in one pass.

SAMACH’s Edge Banding Machine gives manufacturers the tools to execute this process with speed, uniformity, and precision—ideal for furniture, cabinet, and display industries.

Why SAMACH Stands Out in Woodworking Technology

- Versatile Machinery Range

From edge banding to sanding and routing, SAMACH provides a diverse range of Woodworking Machines—all designed to complement each other on the shop floor. - Focus on Intelligent Solutions

Their tagline—“Professional solutions for intelligent furniture”—signals a commitment to enabling smarter, digital workflows. - Global Visibility & Support Networks

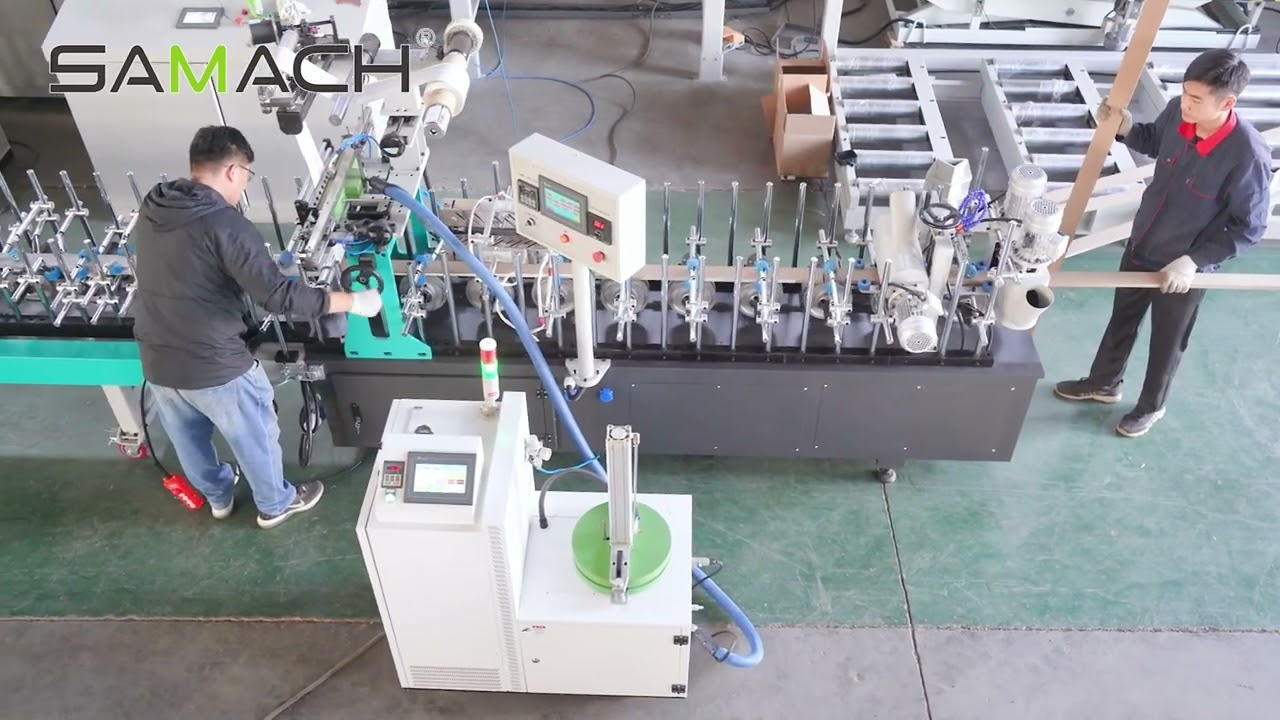

SAMACH maintains a presence on platforms like Instagram and YouTube, showcasing their machines in action—e.g., “SAMACH Profile Shapes Edge Banding Machine” videos displaying real-world application. - Broad Industrial Applicability

Their machines suit wood-based panel operations as well as solid wood and metal workflows—making them adaptable to a wide range of factory layouts and product styles.

SAMACH in Action: Practical Applications & Advantages

A. Furniture Manufacturers and Cabinetry

- Problem: Achieving edge consistency and durability in high-volume projects.

- Solution: Use SAMACH’s Edge Banding Machine to quickly seal edges, improving both appearance and longevity.

- Result: Higher output speeds and reduced rework rates.

B. Bespoke Workshops

- Problem: Balancing craftsmanship with precision in custom orders.

- Solution: Incorporate SAMACH’s CNC Router and Edge Banding Machine for precision cuts and flawless edges.

- Result: Consistent, repeatable quality that still exhibits artisan-level finish.

C. Integrated Factory Operations

- Problem: Coordinating panel preparation, finishing, and joinery processes in one continuous workflow.

- Solution: Deploy a combination of SAMACH’s Sanding Machine, Edge Banding Machine, Painting Machine, and panel processing units.

- Result: Streamlined production paths, minimal material handling, and reduced labor costs.

Technical Edge: What SAMACH Brings to the Table

1. Automation and Efficiency

Their suite of machines supports automation—from automated feeding and trimming in Edge Banding Machines to multi-axis routing and drilling systems, enabling high throughput with minimal manual intervention.

2. Precision and Quality Control

SAMACH machines emphasize tight tolerances, smooth bonding, and clean finishes—vital for meeting standards in furniture displays, kitchen installations, and retail-grade joinery.

3. Modular & Scalable Systems

A factory can begin with an Edge Banding Machine or a CNC router and gradually integrate other SAMACH machines like sanders, panel saws, or painters as demand grows—creating a scalable manufacturing infrastructure.

SAMACH’s Brand Engagement & Support Infrastructure

SAMACH isn’t just a manufacturer—they actively engage with their audience through:

- Instagram (“samachwoodworking”), sharing images and updates under “Professional solutions for intelligent furniture”.

- YouTube, offering demonstration videos including one titled “SAMACH Profile Shapes Edge Banding Machine”—perfect for understanding user experiences and machine capabilities.

- Exhibitions and About Us segments on their site, each likely providing insights into their ethos, showrooms, and technology roadmap.

These platforms help customers visualize integration potential and support performance expectations.

Putting It All Together: Sample Workflow in a Modern Facility

- Initial Panel Preparation: Use a panel saw or CNC router to cut to size.

- Joinery or Routing: Apply drilling, routing, or finger-joint processing as needed.

- Surface Finishing: Sand and paint using SAMACH’s finishing machines.

- Edge Sealing: Execute final edge treatment via the Edge Banding Machine—combining adhesive, tape application, trimming, and buffing in one efficient pass.

- Final Inspection & Packaging

This approach encapsulates an efficient factory floor—one where every Woodworking Machine has a purpose, and the Edge Banding Machine adds the professional touch that makes panels market-ready.

Benefits Recap: SAMACH’s Value Proposition

| Feature | Benefit |

|---|---|

| Complete machinery ecosystem | Streamlined workflows across all stages of production |

| Intelligent automation | Higher throughput, reduced labor, consistent output |

| Precision craftsmanship tools | Clean, high-quality edges and finishes at speed |

| Scalability | Invest in stages—start small and grow machinery setup |

| Global showcase & support | Media presence provides transparency and confidence |

Conclusion

When it comes to modern furniture production, margins are tight and standards are high. With SAMACH’s integrated suite—anchored by the Edge Banding Machine and supported by a full lineup of Woodworking Machines—manufacturers gain the twin advantages of automation and artisanal-quality finish. From reducing labor and speeding throughput to elevating the final appearance, SAMACH empowers businesses to produce smarter, cleaner, and more efficiently.

For anyone dedicated to elevating their manufacturing workflow—whether a workshop, custom furniture studio, or high-output factory—SAMACH offers the tools, technology, and support to make that vision a reality.