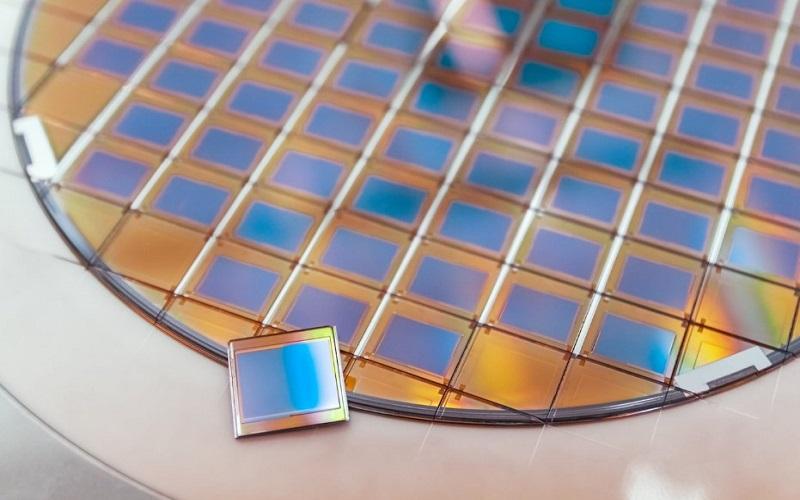

Wafer dicing is a semiconductor manufacturing process where a thin semiconductor wafer, often made of materials like silicon, gallium arsenide, or silicon carbide, is cut or diced into individual chips or dies. These chips are used to create electronic components like integrated circuits (ICs) and microchips. A wafer dicing service is a specialized service that provides the equipment and expertise for this precise and delicate process.

Wafer dicing service overview

Here’s an overview of what a wafer dicing service does:

Wafer Preparation: The service begins with the customer providing the semiconductor wafer. This wafer may contain numerous identical integrated circuits, and the dicing service’s primary task is to separate these circuits into individual chips.

Dicing Process: The dicing service uses specialized equipment, such as dicing saws or laser dicing machines, to perform the cutting process. The choice of equipment depends on the material, dimensions, and precision required for the dicing. Dicing saws use diamond blades, while laser dicing uses high-energy lasers to make precision cuts.

Alignment and Precision: Ensuring the accurate alignment of the dicing process is crucial. Dicing services use advanced techniques to align the cutting process with the existing features on the wafer, such as patterns or markings.

Wafer Handling: After dicing, the individual chips or dies are extremely delicate and must be handled with care. The dicing service may use specialized tools or robotics to handle and package the diced chips.

Quality Control: Quality control and inspection are essential steps. The dicing service checks the dimensions, alignment, and quality of the diced chips to ensure they meet the customer’s specifications.

Tape and Mounting: In some cases, the diced chips are mounted onto tape or other substrates for ease of handling or to prepare them for subsequent assembly processes.

Cleaning and Packaging: Cleanliness is vital in semiconductor manufacturing. The dicing service may clean the diced chips to remove any contaminants or debris. The chips are then typically packaged in trays or other appropriate containers to protect them during shipping.

Delivery: Once the chips are diced, inspected, and prepared, they are ready for delivery to the customer. They can be used in the production of electronic devices, such as microprocessors, memory chips, sensors, and other semiconductor components.

Final Words

Wafer dicing services are commonly used in the semiconductor industry, where precision and quality are paramount. These services save semiconductor manufacturers time and resources by providing expertise, equipment, and processes necessary to create individual chips from large semiconductor wafers. The resulting chips can be integrated into a wide range of electronic devices, contributing to the advancement of technology and the manufacturing of electronic products.