In the vast industry of machinery, screw vacuum pumps have come to be seen as vital tools because of their effectiveness, reliability as well as their adaptability. They play an essential part in a variety of sectors, from chemical processing to food manufacturing. Knowing the advantages of screw vacuum pumps can benefit companies increase their processes to reduce downtime and boost efficiency.

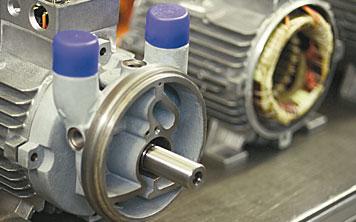

Understanding Screw Vacuum Pumps

Pumps for screws are pumps with positive displacement made of rotating rotors in the shape of a screw to reduce and move gasses. They do not have internal lubrication which reduces wear and contamination and makes them suitable for demanding industrial applications. Rotors rotate in opposing directions, capturing gas while diminuting its size, creating a vacuum.

Superior Efficiency and Energy Conservation

One of the most notable benefits of screw vacuum pumps is their effectiveness. They maintain constant pressure levels and require low energy use. Contrary to other kinds of vacuum pumps that use screw pumps, they employ direct drive technology that reduces energy losses and boosts overall efficiency. This payoff is substantial energy savings and is an important factor in industries that are looking to reduce expenses for operations and reduce the carbon footprint.

Minimal Maintenance and Longevity

Screw vacuum pumps are designed to last and need minimal maintenance. Lack of internal lubrication makes it less prone to wear and wear and tear. In addition, the rotors and housings are constructed from top-quality components that are resistant to wear and tear as well as mechanical stress. Therefore, the pumps can provide a longer life span as compared to other vacuum pumps. which reduces maintenance time and cost and guarantees uninterrupted operation for crucial industrial processes.

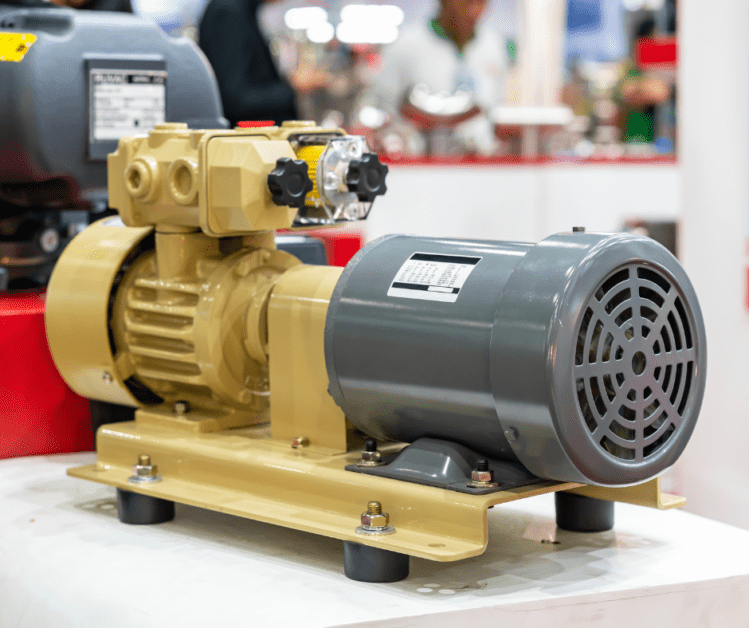

Versatile Applications

The variety of these pumps makes the pumps appropriate to be used in a variety of uses. They are frequently employed in the pharmaceutical and chemical sectors, where keeping an environment free of contamination is vital. Furthermore, they are used for food processing packaging, and material handling. The ability of these pumps to deal with various gases and vapors safely makes them more effective in diverse industries.

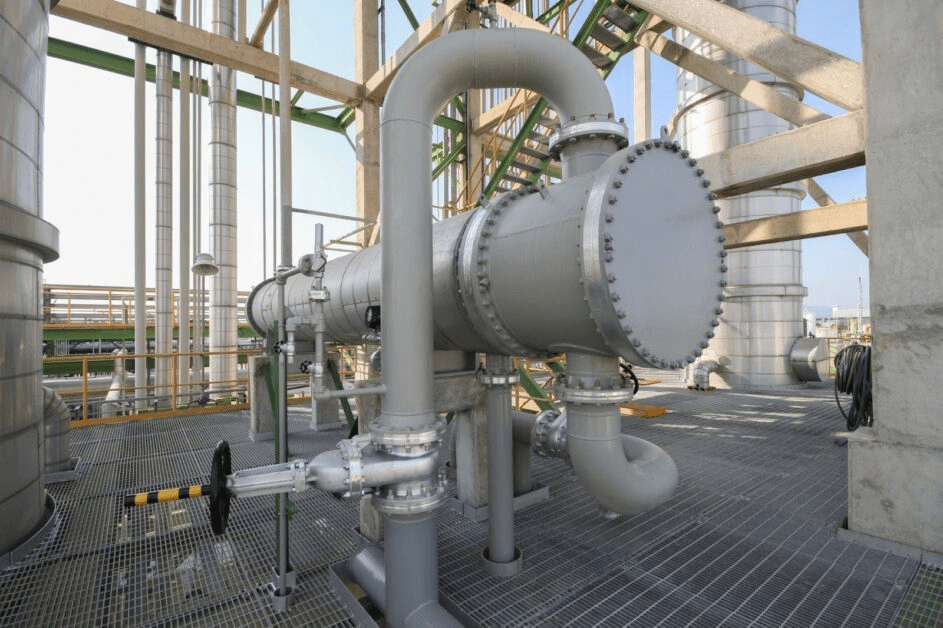

Increased Performance with Heat Exchangers

The integration of screw vacuum pumps into heat exchangers will significantly improve the performance of these pumps. Heat exchangers benefit from managing the heat load produced during compression and benefit from maintaining optimal operating temperatures. This combination not only increases the effectiveness of the vacuum pump but also increases its life by preventing excessive heat. Industries that need exact temperatures, such as semiconductor production and pharmaceutical manufacturing are greatly benefited by this mix.

Environmental Benefits

Screw vacuum pumps have several environmental benefits. They are oil-free, which reduces contamination risk, which makes them suitable for use in cleanrooms and other applications in which air purity is essential. In addition, the superior efficiency and energy-saving aspects of screw vacuum pumps help to reduce greenhouse gas emissions. When choosing screw and vacuum pumps companies can fulfill their goals for sustainability with high operating standards.

Quiet Operation

Noise pollution is a major problem in many industries. The screw vacuum pumps run quieter than other kinds of vacuum pumps, like piston pumps or rotary vanes. The quiet operation of screw rotors helps reduce vibration and noise. This creates a quieter working space. This is particularly important for industries where an environment that is quiet and peaceful is essential to warrant the safety and security of workers.

Cost-Effectiveness

Although the initial cost of screw vacuum pumps could be greater than the other kinds of pump, the value for money is undisputed. A combination of high efficiency and energy efficiency, as well as low maintenance needs, and a longer duration of use payoff in substantial savings over the long run. Industries can anticipate a rapid ROI, which makes screw vacuum pumps an economically efficient choice for the long term.

Conclusion

The screw vacuum pumps are indispensable in the modern industrial world due to their efficacy as well as their reliability and flexibility. The ability of these pumps to function without internal lubrication helps reduce the risk of contamination and maintenance, and their energy efficiency can reduce usage. If combined with heat exchangers pumps can serve improved performance as well as a long service life which makes these pumps appropriate to be used in a range of different fields. Additionally, their benefits for the environment as well as their quiet operation enhance their value. The investment in a screw vacuum pump guarantees optimal performance, a huge reduction in costs, as well as a less carbon footprint. While industries are constantly seeking new ways to raise their processes and processes, screw vacuum pumps stand in the spotlight as an important element to getting operational efficiency.