Vacuum technology plays a crucial role in various industrial and scientific applications, from maintaining precise conditions in manufacturing processes to enabling complex research experiments. Among the many vacuum pump technologies available, Elmo Rietschle vacuum pumps stand out due to their innovative design and exceptional performance. In this blog, we’ll explore the distinctive features of these vacuum pumps, their advantages, and how they compare to other technologies.

Understanding Vacuum Technology

Vacuum technology involves creating and maintaining a low-pressure environment within a sealed space. This low-pressure environment is essential for various processes, including:

- Material Handling: Ensuring the safe and efficient movement of materials without contamination.

- Chemical Processing: Preventing unwanted reactions by maintaining a controlled atmosphere.

- Manufacturing: Improving the quality and efficiency of production processes.

- Research and Development: Providing precise conditions for experiments and analyses.

Vacuum pumps are the heart of vacuum technology, responsible for creating and maintaining the desired vacuum levels.

The Basics of Vacuum Pumps

Vacuum pumps work by removing air and other gases from a chamber to create a vacuum. There are several types of vacuum pumps, each designed for specific applications:

- Rotary Vane Pumps: Known for their reliability and efficiency in creating low to medium vacuums.

- Diaphragm Pumps: Ideal for applications requiring high chemical resistance and clean operation.

- Scroll Pumps: Offer a quiet and oil-free vacuum solution, suitable for sensitive applications.

- Turbo Molecular Pumps: Designed for ultra-high vacuum applications, providing very low pressure levels.

The Elmo Rietschle Vacuum Pumps: Key Features and Advantages

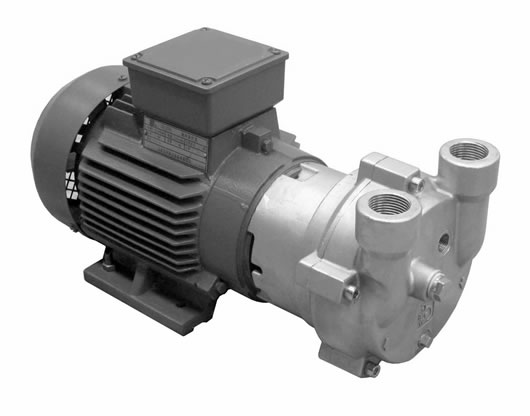

Elmo Rietschle vacuum pumps are renowned for their advanced technology and exceptional performance. Here’s what sets them apart:

1. Advanced Engineering and Design

Elmo Rietschle vacuum pumps are engineered with cutting-edge technology to ensure optimal performance and reliability. Their design incorporates:

- High Efficiency: These pumps deliver superior performance while minimizing energy consumption.

- Robust Construction: Built with high-quality materials to withstand demanding industrial environments.

- Quiet Operation: Designed to operate quietly, reducing noise pollution in the workplace.

2. Versatility and Flexibility

Elmo Rietschle vacuum pumps are versatile and suitable for a wide range of applications. They offer:

- Variable Speed Control: Allows for precise adjustment of pump speed to match specific process requirements.

- Modular Design: Facilitates easy integration into existing systems and customization based on needs.

- Wide Pressure Range: Capable of handling various pressure levels, from low to high vacuums.

3. Reliability and Durability

Reliability is a key factor in vacuum technology, and Elmo Rietschle vacuum pumps excel in this area. They feature:

- Long Service Life: Designed for extended operation with minimal maintenance requirements.

- High Durability: Engineered to perform consistently even under harsh conditions.

- Advanced Diagnostics: Equipped with monitoring and diagnostic tools to ensure optimal performance and early detection of issues.

4. Energy Efficiency and Cost Savings

Energy efficiency is a critical consideration in modern vacuum technology. Elmo Rietschle vacuum pumps offer:

- Reduced Energy Consumption: Their efficient design helps lower energy costs.

- Lower Operating Costs: Minimal maintenance and high reliability contribute to cost savings over the pump’s lifespan.

Comparing Vacuum Technologies

When evaluating vacuum pump technologies, it’s essential to consider various factors such as performance, efficiency, and application suitability. Here’s a comparison of Elmo Rietschle vacuum pumps with other common types:

1. Rotary Vane Pumps vs. Elmo Rietschle Vacuum Pumps

- Performance: Elmo Rietschle vacuum pumps often provide higher efficiency and better performance across a broader range of applications compared to traditional rotary vane pumps.

- Noise Levels: Elmo Rietschle vacuum pumps are designed for quieter operation, whereas rotary vane pumps can be noisier.

- Energy Efficiency: Elmo Rietschle vacuum pumps typically offer better energy efficiency, leading to lower operational costs.

2. Diaphragm Pumps vs. Elmo Rietschle Vacuum Pumps

- Chemical Resistance: Diaphragm pumps excel in applications requiring high chemical resistance, while Elmo Rietschle vacuum pumps may have more versatile applications but might not match the chemical resistance of diaphragm pumps.

- Maintenance: Elmo Rietschle vacuum pumps generally require less frequent maintenance compared to diaphragm pumps, which may need regular servicing.

3. Scroll Pumps vs. Elmo Rietschle Vacuum Pumps

- Oil-Free Operation: Scroll pumps offer oil-free operation, which can be beneficial for certain applications. Elmo Rietschle vacuum pumps may have options for oil-free or oil-lubricated models depending on the application requirements.

- Cost: Scroll pumps can be more expensive, while Elmo Rietschle vacuum pumps provide a range of options to suit different budget constraints.

Integrating Vacuum Pumps with Other Technologies

In many industrial systems, vacuum pumps work in conjunction with other technologies to enhance overall performance. For example:

- Brazed Plate Heat Exchangers: These are used in conjunction with vacuum pumps to manage heat transfer efficiently. Brazed plate heat exchangers offer high thermal performance and compact design, making them ideal for applications where space is limited.

Conclusion

Elmo Rietschle vacuum pumps represent a significant advancement in vacuum technology, offering exceptional performance, versatility, and efficiency. Their advanced engineering and design make them a preferred choice for various industrial applications. By understanding the distinctive features and benefits of these vacuum pumps, you can make informed decisions and optimize your systems for better performance and cost savings.

Whether you’re looking to enhance your existing setup or explore new technologies, Elmo Rietschle vacuum pumps provide a reliable and effective solution. Combine them with complementary technologies like brazed plate heat exchangers to achieve optimal results and drive success in your industrial processes.