The fast-paced manufacturing environment of today makes quality control more crucial than ever. Traditional methods often fail to provide consistent product quality, especially as manufacturing quantities and complexity increase.

This is where artificial intelligence (AI) comes in handy. By using AI, businesses can revolutionize their quality control processes and achieve increased productivity, accuracy, and overall product perfection.

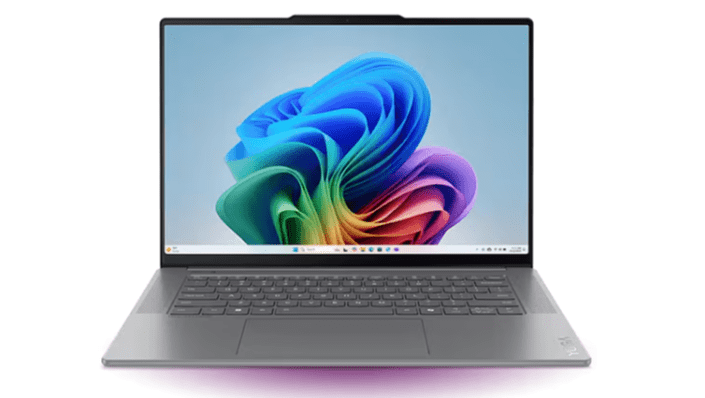

Modern image recognition technologies in smart AI-powered laptops make it simpler for manufacturers to separate high-quality items from low-quality ones. Learn how AI in the manufacturing process helps businesses meet quality control needs.

How AI Transforms Quality Control

AI-driven quality control systems use modern technology like computer vision, machine learning, and deep learning to automate and enhance the inspection process. Here are a few areas where AI is making a significant impact:

1. Flaw Detection and Product Inspection

AI-based systems can increase fault detection rates by up to 90% when compared to human inspection rates.

Product inspection and flaw identification are two of the main uses of AI-powered machine vision in quality control. Cameras and other sensors can use machine vision to take pictures of goods as they pass by robotic systems or conveyor belts.

After that, artificial intelligence systems can examine these photos to find flaws like dents, cracks, discolorations, and other issues that might not be immediately apparent to the human eye.

2. Predictive Maintenance Analysis

Predictive maintenance is a proactive approach to maintenance that uses AI algorithms to assess sensor data from industrial equipment and identify any faults before they occur.

Businesses can reduce downtime and increase overall equipment dependability by scheduling preventative maintenance when they notice indicators of wear and tear or unusual operating circumstances.

For example, an artificial intelligence program can use vibration data from a manufacturing machine to predict when a bearing will break. So, businesses can replace the bearing before it breaks, ensure continuous production, and save money on costly downtime.

3. Management of Supply Chain

The impact of the microprocessor shortage on the automotive industry is one recent example of how supply chain disruptions at one point can have significant downstream effects.

The supply chain management problem is especially well-suited for artificial intelligence because it combines large amounts of data and necessitates optimization across multiple parameters.

In terms of manufacturing quality, however, businesses can use AI to combine this data with supplier performance data, like delivery schedules and costs, to ensure consistent product quality throughout their entire supply chain.

4. Increased Efficiency and Speed

In today’s production, speed is essential. Conventional quality control techniques often struggle to match the rapid production of high-speed manufacturing lines. AI-enabled machine vision systems enable them to analyze visual data instantly, enabling them to inspect items at the same speed as the production line.

It can also be utilized for sorting and counting. As a result, you can maintain high standards of quality without compromising productivity. This also increases production and reduces the need for manual intervention.

For example, Intel offers a powerful toolkit for machine vision solutions. Machine vision is the application of advanced AI technology to industrial machinery so that it can view and assess tasks associated with smart manufacturing, quality assurance, and worker safety.

5. Foresee Supply and Demand

AI can simulate lead times and anticipated market demand to help firms accurately forecast supply and demand. Businesses that take this approach can anticipate supply chain delays and ensure that they have adequate inventory to meet customer demand.

Manufacturers can increase their business’s productivity and profitability by employing AI to help them make educated decisions regarding inventory control and production scheduling.

6. Industrial Ai in Manufacturing

Machine vision and artificial intelligence integration into industrial processes are included in industrial artificial intelligence. AI technologies are being used to optimize various industrial processes, including manufacturing, supply chain management, quality assurance, and predictive maintenance.

Manufacturing Artificial Intelligence enables manufacturers to achieve predictable and stable product quality while minimizing human error and variability in quality control.

Future of Quality Control

AI will surely play a major role in quality control in manufacturing in the future. As AI technology develops, we might expect even greater levels of accuracy, speed, and predictive capacity. Manufacturers will become more competitive and will establish new standards for excellence in the industry if they use AI-powered quality control.

To Sum Up

Artificial intelligence (AI) is transforming quality control and giving companies the resources they need to guarantee product excellence in the cutthroat market of today. Employing intelligent AI-enabled laptops and further AI technologies can help businesses increase productivity, accuracy, and customer happiness.