In the landscape of industrial thermal management, air cooled heat exchangers represent a pivotal technology, delivering essential cooling without relying on water resources. This guide explores the premier air cooled heat exchanger products manufactured in the USA, offering a detailed examination of their features, advantages, and selection criteria to help you choose the best solution for your specific requirements.

The Essentials of Air Cooled Heat Exchangers

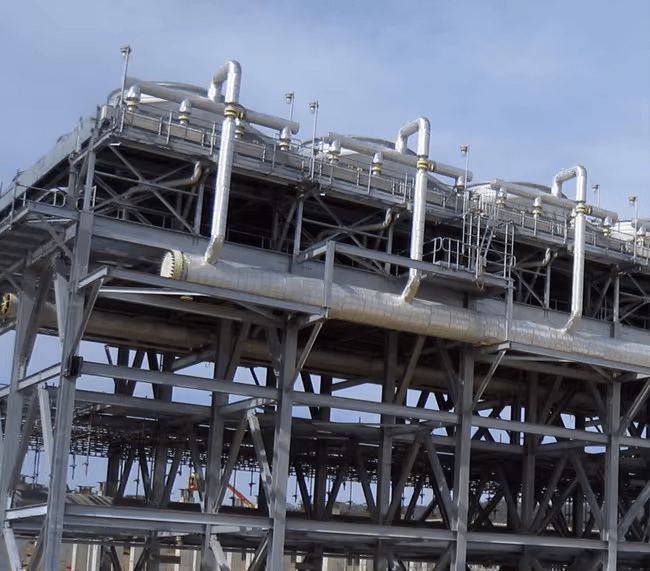

Air cooled heat exchangers are engineered to utilize ambient air for cooling process fluids, making them an indispensable choice in applications where water availability is restricted or its use is constrained. These systems are designed to efficiently transfer heat from the process fluid to the ambient air, enabling effective cooling with minimal water consumption.

Unlike water-cooled systems, which depend on a separate water supply and often require complex water treatment, air cooled heat exchangers simplify the cooling process by eliminating these dependencies. Their design typically involves a series of finned tubes or coils, which maximize the surface area exposed to the air, enhancing heat dissipation.

Key Attributes of Leading Air Cooled Heat Exchangers

When evaluating top-tier air cooled heat exchangers, several critical attributes should be considered to ensure optimal performance and reliability:

- Thermal Performance: The efficacy of a heat exchanger is largely determined by its thermal performance. High-quality air cooled heat exchangers are designed to achieve superior heat transfer rates, ensuring that the process fluids are cooled efficiently and effectively.

- Construction and Durability: The construction materials used in air cooled heat exchangers are crucial for their longevity and resilience. Premium products often feature robust materials such as stainless steel or high-grade aluminum, which offer resistance to corrosion, abrasion, and harsh environmental conditions.

- Energy Efficiency: Modern air cooled heat exchangers are designed with energy efficiency in mind. Advanced technologies and engineering innovations help reduce energy consumption and operational costs, contributing to more sustainable and cost-effective cooling solutions.

- Size and Capacity: It is essential to select a heat exchanger that matches your cooling needs precisely. The size and capacity of the unit should align with the thermal load requirements of your application to avoid inefficiencies or over-specification.

- Maintenance and Accessibility: Ease of maintenance is a significant factor in the overall efficiency of a heat exchanger. Models that feature accessible components, such as removable filters and service panels, simplify routine maintenance and reduce downtime.

Varieties of Air Cooled Heat Exchangers

Several types of air cooled heat exchangers cater to different industrial needs:

- Fin Tube Heat Exchangers: This type incorporates a network of fins attached to tubes, enhancing the surface area for heat exchange. It is widely used in various applications due to its efficiency in heat transfer and straightforward design.

- Shell and Tube Heat Exchangers: In this design, process fluid flows through tubes encased in a shell. Air circulates over the shell to remove heat. This robust configuration is favored for its high heat transfer capacity and durability.

- Plate Heat Exchangers: Though less common for air cooling, plate heat exchangers feature a series of stacked plates that provide high heat transfer efficiency in a compact form. They are typically used in liquid-to-liquid cooling but can be adapted for specialized air cooling applications.

- Spiral Heat Exchangers: Spiral heat exchangers utilize a unique spiral design to maximize the heat exchange surface area. This configuration is particularly effective for handling viscous or fouling fluids. While less common in air cooling, they offer distinct advantages for specialized industrial applications.

Advantages of Air Cooled Heat Exchangers

The use of air cooled heat exchangers offers several compelling benefits:

- Water Conservation: By eliminating the need for a water supply, these heat exchangers contribute significantly to water conservation efforts, making them ideal for regions where water is a limited resource.

- Lower Operational Costs: The absence of a water cooling circuit reduces associated costs, including water treatment and disposal. This can lead to substantial savings in operating expenses over the life of the equipment.

- Simplified Maintenance: With fewer components and no water system to manage, air cooled heat exchangers often require less maintenance compared to their water-cooled counterparts. This simplicity translates into reduced maintenance efforts and lower long-term costs.

- Environmental Impact: Using air instead of water for cooling minimizes environmental impact, aligning with sustainable practices and regulatory requirements focused on reducing water usage.

Choosing the Optimal Air Cooled Heat Exchanger

Selecting the right air cooled heat exchanger involves several considerations:

- Application Specifics: Analyze the requirements of your application, including the thermal load, fluid properties, and spatial constraints. This assessment will guide you in choosing a heat exchanger that meets your needs effectively.

- Environmental Conditions: The operating environment can influence the performance of the heat exchanger. Ensure that the unit is designed to withstand the local climate and environmental factors.

- Compliance and Standards: Verify that the heat exchanger meets relevant industry standards and regulatory requirements. Compliance ensures that the equipment operates safely and efficiently.

- Cost-Effectiveness: Weigh the initial investment against long-term operational costs. Sometimes, a higher initial expenditure can result in greater energy savings and reduced maintenance over time.

Conclusion

In summary, air cooled heat exchangers offer a versatile and efficient solution for industrial cooling applications, particularly where water conservation and simplified maintenance are priorities. By understanding the various types, features, and benefits of these systems, you can make an informed decision that enhances your operational efficiency and aligns with environmental sustainability goals. Investing in high-quality air cooled heat exchangers from reputable manufacturers in the USA ensures reliable performance and long-term value, making them a prudent choice for your cooling needs.

4o mini