In the dynamic landscape of industrial packaging, efficiency, durability, and cost-effectiveness are paramount considerations. Among the myriad tools and technologies available, Polyolefin (POF) shrink film machines have emerged as indispensable assets for businesses seeking to streamline their packaging processes. These machines offer a versatile and reliable solution for various industrial applications, ranging from food packaging to electronics and beyond. Let’s delve into the intricacies of POF shrink film machines and explore their significance in modern industrial settings.

Understanding POF Shrink Film Machines

POF shrink film machines are instrumental in the packaging industry for their ability to encapsulate products securely and present them attractively. Polyolefin, the material from which the shrink film is derived, is renowned for its durability, clarity, and versatility. POF shrink film machines utilize this material to create tightly wrapped packages, ensuring product protection and presentation.

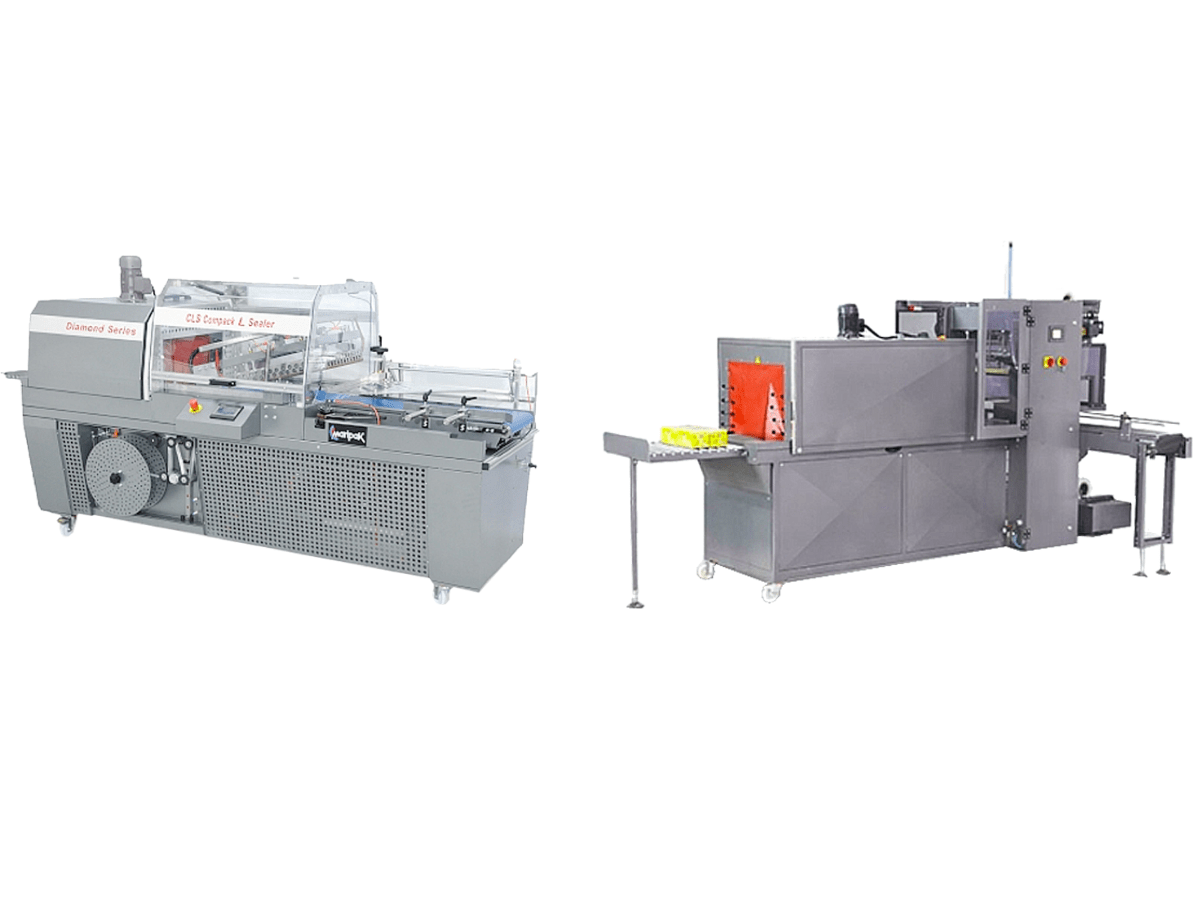

These machines typically consist of a conveyor belt system, a sealing mechanism, and a heat tunnel. The process begins with the product being placed on the conveyor belt, where it is then enclosed in the POF shrink film. The film is sealed using heat, and as the package passes through the heat tunnel, the film shrinks, conforming tightly to the product’s shape.

Applications Across Industries

The versatility of POF shrink film machines makes them suitable for a wide array of industries:

- Food and Beverage: In the food industry, POF shrink film machines are used to package items such as trays of meat, poultry, and cheese, as well as baked goods and confectionery. The tight seal created by the shrink film helps preserve freshness and extend shelf life.

- Pharmaceuticals: Pharmaceutical products require secure and tamper-evident packaging to maintain product integrity. POF shrink film machines ensure that medicines and medical devices are safely packaged, protecting them from contamination and tampering.

- Electronics: Electronic components and devices are often delicate and susceptible to damage. POF shrink film machines provide a protective barrier, safeguarding these items during storage and transit.

- Cosmetics and Personal Care: Beauty and personal care products benefit from the aesthetic appeal of shrink-wrapped packaging. POF shrink film machines enhance the visual presentation of cosmetics while providing protection against moisture and external elements.

Advantages of POF Shrink Film Machines

The adoption of POF shrink film machines offers several advantages for industrial packaging operations:

- Versatility: POF shrink film machines can accommodate a wide range of product shapes and sizes, making them suitable for diverse packaging needs.

- Durability: Polyolefin shrink film is tear-resistant and puncture-proof, providing robust protection for packaged goods.

- Clarity: The high clarity of POF shrink film enhances product visibility, allowing for effective branding and marketing.

- Cost-effectiveness: Compared to other packaging materials, POF shrink film offers a cost-effective solution without compromising on quality or performance.

- Environmental Friendliness: POF shrink film is recyclable, making it an environmentally sustainable choice for packaging applications.

Innovations in POF Shrink Film Machines

The advancements in technology continue to enhance the capabilities and functionalities of POF shrink film machines, enabling businesses to further optimize their packaging processes. Some notable innovations include:

- Automated Systems: Integration of automation into POF shrink film machines streamlines production processes, reducing manual intervention and increasing efficiency. Automated systems can handle tasks such as product feeding, film cutting, sealing, and shrinking, allowing for higher throughput and productivity.

- Precision Control: Modern POF shrink film machines are equipped with advanced control systems that enable precise adjustment of temperature, conveyor speed, and shrink film tension. This level of control ensures consistent and uniform shrinkage, resulting in high-quality packaging.

- Multi-Layer Films: Manufacturers are developing multi-layer POF shrink films that offer enhanced barrier properties, such as improved moisture resistance and oxygen barrier. These films are particularly beneficial for packaging perishable goods and sensitive products that require extended shelf life.

- Energy Efficiency: Energy-efficient designs and features are being incorporated into POF shrink film machines to reduce energy consumption and operational costs. Heat recovery systems, insulated tunnels, and programmable controls contribute to energy savings without compromising on performance.

Conclusion

In the competitive landscape of industrial packaging, efficiency, durability, and presentation are critical factors influencing consumer perception and operational success. POF shrink film machines offer a reliable and versatile solution for businesses seeking to optimize their packaging processes. From food and beverages to electronics and beyond, these machines play a pivotal role in ensuring product protection, enhancing visual appeal, and driving operational efficiency. As industries continue to evolve, POF shrink tunnel will undoubtedly remain indispensable assets for businesses striving to meet the demands of modern packaging standards.