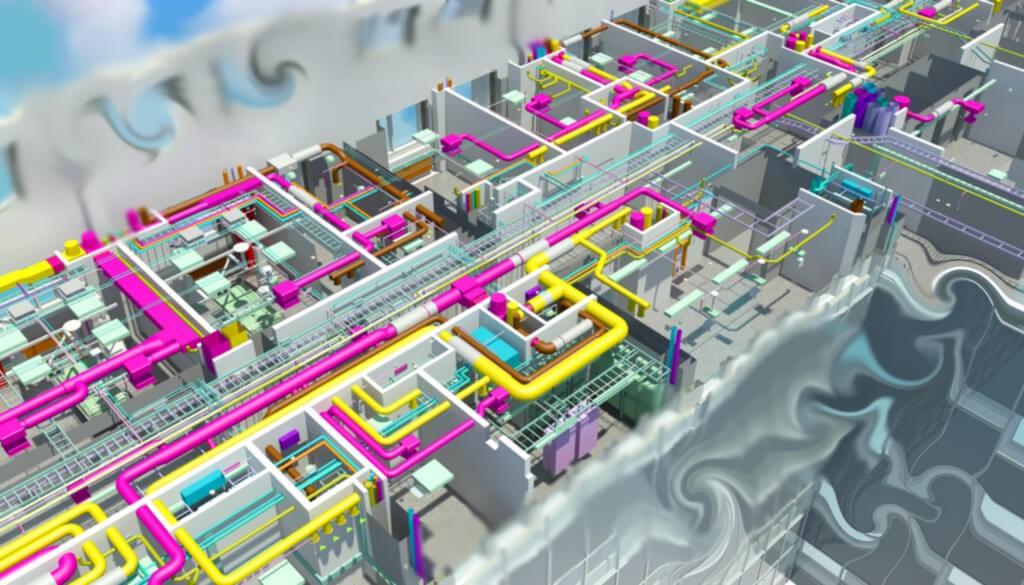

MEP Design:

Mechanical, Electrical, and Plumbing (MEP) systems form the backbone of every modern building, ensuring comfort, function, safety, and energy efficiency. While MEP design is often associated with these essential services, its role in mitigating or preventing structural movement issues is equally important. Buildings naturally move due to temperature changes, load variations, settlement, vibrations, and environmental factors, but when movement is excessive or unmanaged, it can lead to damage, system failure, or safety risks.

Understanding Structural Movement During a Building’s Life Cycle

Structural movement refers to the shifts, deformation, or displacement that occur in a building’s frame or foundation. Some movement is normal, such as minor settling or thermal expansion, while major shifts can signal structural failure. Even small changes can affect MEP systems because these installations are connected throughout the building’s walls, slabs, ceilings, and floors.

Common causes of structural movement include soil settlement, differential loads, thermal expansion, seismic activity, and vibration from equipment or traffic. When MEP systems are designed without considering these forces, pipes may crack, ducts may detach, cables may stretch, or equipment may become misaligned. Therefore, integrating structural considerations into MEP design is essential for long-term building performance.

How MEP Systems Influence and Respond to Structural Movement

MEP systems interact closely with the building structure. Large HVAC units, water-filled pipes, heavy electrical panels, and suspended ductwork add weight and generate forces that can influence movement. At the same time, these systems must be flexible enough to absorb or accommodate the building’s natural shifts.

For example, plumbing systems experience pressure variations when the building moves. Electrical conduits may pull against junction boxes, while HVAC ducting may distort under stress. Designing for these interactions helps ensure that movement does not lead to operational issues or safety hazards.

Importance of Load Distribution in MEP Design

Uneven distribution of weight from MEP equipment can strain structural elements. Heavy machinery like chillers, boilers, transformers, and large air-handling units must be placed carefully to avoid overloading beams or slabs.

MEP engineers work with structural engineers to calculate load requirements, ensuring that equipment rests on reinforced sections of the building. Proper load planning prevents excessive deflection or settlement, which in turn protects the building from long-term structural instability.

Allowing Flexibility Through Expansion Joints and Supports

One of the most important tools used by MEP designers to prevent structural movement issues is flexibility. Expansion joints, isolation joints, and flexible connectors allow pipes and ducts to shift slightly with the building without breaking or causing stress.

Plumbing systems often require multiple expansion loops or offsets to handle changes in length due to temperature fluctuations. HVAC ductwork benefits from flexible connections that reduce vibration and transfer of movement. Electrical conduits are designed with slack or articulated pathways to avoid stretching or cracking.

These design elements work together to ensure that MEP installations do not become rigid obstacles that restrict natural building movement.

Coordinating MEP Routing to Minimise Structural Weakening

Poorly planned MEP routing can weaken key structural components. For instance, drilling multiple openings in load-bearing walls or beams to pass pipes and conduits can compromise structural integrity.

Good MEP design ensures:

- Minimal penetrations in structural elements

- Proper alignment with designated service zones

- Safe spacing from columns, beams, and core walls

- Routing through areas engineered for openings

Protecting Foundations Through Smart Plumbing and Drainage Design

Water is one of the biggest contributors to structural movement. Poor drainage, leaking pipes, or improper waste line design can cause soil erosion, subsidence, or swelling around the foundation.

MEP design helps prevent these problems through:

- Strategic placement of drainage systems

- Use of waterproofing around plumbing lines

- Correct grading to move water away from the building

- Monitoring systems that detect leaks early

Using Technology to Predict and Minimise Future Movement

Modern MEP design uses advanced technology to anticipate and prevent movement issues. Building Information Modelling (BIM) allows engineers to simulate how systems and structures will interact over time. Structural monitoring data can also be incorporated to predict how movement may affect MEP systems in the future.

Sensor-based systems can monitor real-time vibrations, moisture levels, and thermal changes. MEP engineers can use this data to design systems that adapt to evolving structural behaviour, ensuring long-lasting performance and safety.

Conclusion:

Structural Movement Monitoringis a natural part of every building’s life cycle, but its impact can be controlled through intelligent MEP design. By understanding the forces that cause movement and collaborating closely with structural engineers, MEP designers create systems that support the building’s overall stability. Through proper load distribution, flexible connections, vibration control, and advanced planning, MEP design plays a crucial role in preventing structural issues before they arise.

A well-designed MEP system does more than supply air, power, and water—it strengthens the structure, protects against damage, and ensures that the building functions safely and efficiently for decades.