In today’s swiftly evolving business and technological landscape, performance is prime, and so is the need to optimize using space. Whether in heating, cooling, or energy transfer structures, systems that maximize overall performance even as minimizing length is vital. This is wherein brazed plate warmth exchangers come into play. These compact gadgets have won substantial recognition for their potential to provide advanced warmness switch in a area-saving format. But what precisely makes brazed plate heat exchangers the satisfactory choice for area-saving solutions? Let’s discover.

Understanding Heat Exchangers

Before diving into the specific advantages of brazed plate warmth exchangers, it’s important to apprehend the role of warmth exchangers in general. In essence, warmth exchangers are devices that transfer warmth between or extra fluids without blending them. They are usually used in various programs together with refrigeration, aircon, heating systems, and power generation.

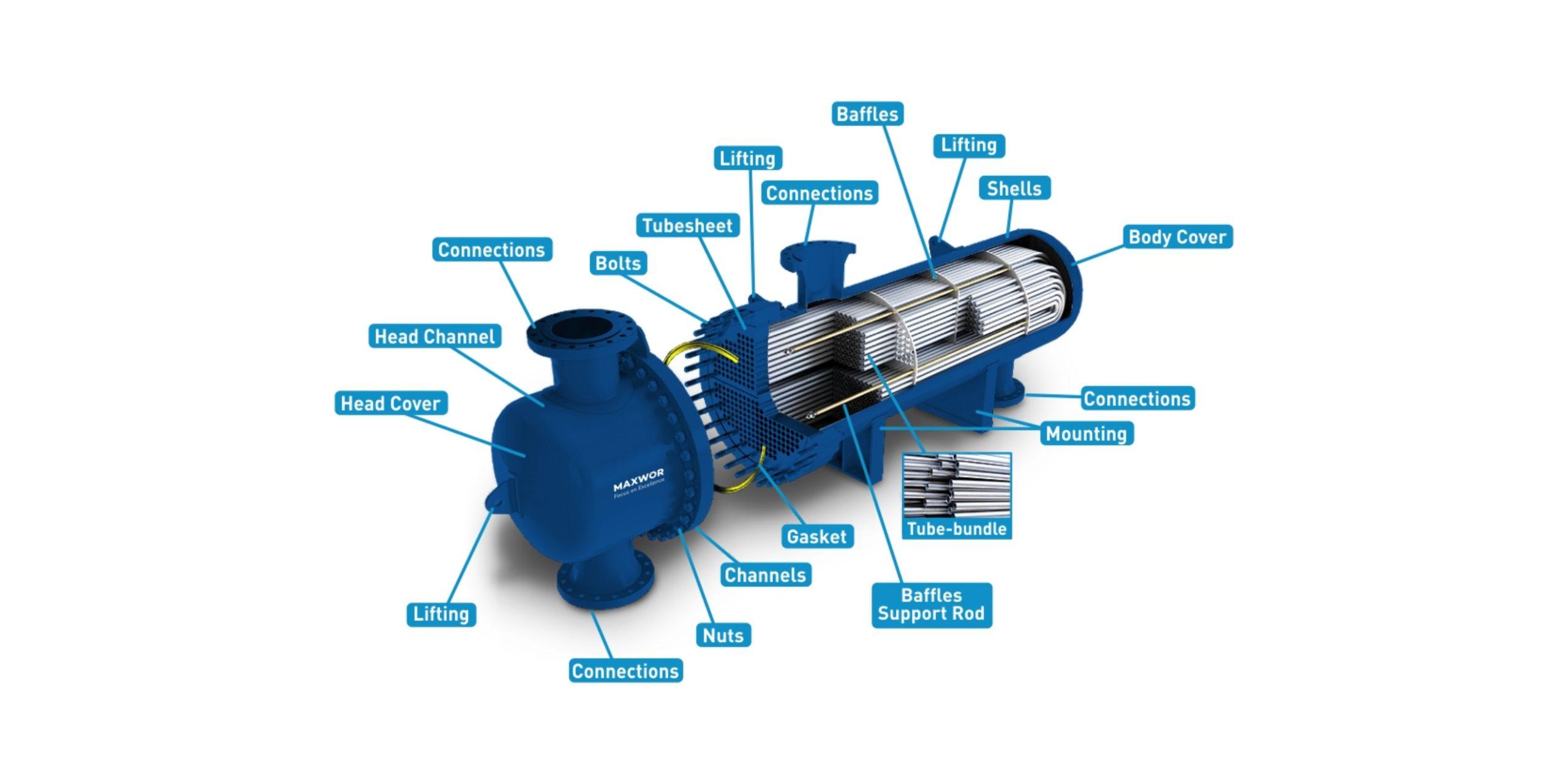

Heat exchangers come in many designs, which includes shell-and-tube, plate-and-frame, and brazed plate sorts. While some of these designs serve the identical fundamental purpose, the choice of warmth exchanger frequently depends on particular software requirements, together with length, cost, and efficiency. For those seeking out a compact, dependable solution, brazed plate warmth exchangers offer distinct blessings.

What Is a Brazed Plate Heat Exchanger?

A brazed plate warmth exchanger consists of more than one thin steel plates stacked collectively. These plates create channels via which warm and bloodless fluids skip, permitting heat to switch from one fluid to the opposite. The plates are “brazed” collectively with a strong, long-lasting fabric, usually copper or nickel, making sure a leak-proof seal. This design now not simplest gives excessive thermal efficiency however additionally reduces the dimensions of the unit as compared to different warmth exchangers like shell-and-tube systems.

The Space-Saving Advantage of Brazed Plate Heat Exchangers

One of the most tremendous advantages of brazed plate warmth exchangers is their compact design. Here are the important thing reasons why they are the best preference for space-saving answers:

- Compact DesignTraditional warmness exchangers inclusive of shell-and-tube designs are frequently cumbersome, requiring a whole lot of space for installation. By comparison, brazed plate warmth exchangers are enormously compact, frequently as much as 90% smaller than different warmness exchangers. This makes them best for applications where area is restrained, inclusive of in commercial HVAC structures, commercial refrigeration, or even in residential heating structures.

- High Heat Transfer EfficiencyDespite their smaller length, brazed plate warmness exchangers are relatively efficient. Their plate-based design permits for a larger floor vicinity for warmth transfer within a smaller footprint. The skinny plates create narrow channels, ensuring that the new and cold fluids bypass very close to each different, maximizing thermal switch. This performance manner that a smaller brazed plate warmness exchanger can achieve the same or higher performance than larger heat exchangers of other designs.

- Lightweight ConstructionIn addition to their compact length, brazed plate warmth exchangers also are lightweight. The plates are made of skinny metal, typically stainless steel, which is both strong and lightweight. The brazing manner guarantees that the unit is long-lasting without the need for heavy external frames or casings. This no longer handiest reduces the load of the unit but additionally makes installation easier and quicker. This is specifically useful in cell packages or structures that require flexibility.

Applications Where Brazed Plate Heat Exchangers Shine

Given their compact size and high performance, brazed plate heat exchangers are utilized in a extensive kind of industries. Some of the maximum commonplace programs where these gadgets shine include:

- HVAC SystemsIn HVAC (heating, air flow, and air con) systems, space is often at a premium. Whether it’s a massive business building or a small residential unit, the capability to in shape effective heat exchangers into tight areas is critical. Brazed plate warmness exchangers are best for HVAC packages because of their small footprint and excessive thermal performance, making them a famous desire for heat healing and warmth transfer structures.

- Refrigeration SystemsIn commercial refrigeration structures, maintaining efficient warmth transfer is essential for reducing strength intake and operating fees. The compact design of brazed plate warmth exchangers makes them perfect for use in refrigeration cycles wherein area is limited. They are normally found in chillers, condensers, and evaporators in both commercial and industrial refrigeration devices.

- Renewable Energy SystemsAs renewable strength turns into greater popular, the call for for green warmth switch structures grows. Brazed plate warmness exchangers are frequently utilized in sun thermal structures and geothermal heat pumps, in which they help switch heat between fluids in a compact, green manner. Their space-saving layout makes them an attractive choice for renewable electricity initiatives, in which maximizing energy performance in small spaces is important.

- Industrial ProcessingIn industries such as chemical processing, food and beverage manufacturing, and prescribed drugs, area is regularly restrained, and the need for efficient warmness switch is excessive. Brazed plate warmth exchangers are typically used in those industries due to their ability to handle high pressures and temperatures while occupying minimal space.

Durability and Maintenance of Brazed Plate Heat Exchangers

One of the motives why brazed plate heat exchangers are taken into consideration the best preference for space-saving answers is their sturdiness. The brazing technique used to enroll in the plates guarantees that the unit is leak-evidence and noticeably proof against corrosion. This makes brazed plate warmness exchangers an outstanding desire for stressful applications that require lengthy-lasting overall performance.

Additionally, brazed plate warmness exchangers require minimum upkeep. Their easy layout with out a gaskets or moving components reduces the likelihood of mechanical failure, which additionally translates to lower upkeep charges. The compact length also makes them easy to clean and service when necessary, similarly including to their convenience.

Energy Efficiency and Cost Savings

Another sizeable benefit of brazed plate warmth exchangers is their power performance. The near proximity of the new and cold fluids within the narrow channels permits for rapid heat transfer, lowering the quantity of energy needed to gain the preferred temperature trade. This stepped forward efficiency can cause vast strength financial savings over time, making brazed plate heat exchangers a price-effective solution for many industries.

Moreover, their compact size no longer handiest saves space but also reduces the fabric prices concerned in manufacturing and transporting the devices. The result is a warmness exchanger that can provide exceptional overall performance at a aggressive fee, making it a smart investment for agencies in search of to optimize their operations.

Conclusion: Why Choose Brazed Plate Heat Exchangers?

In conclusion, brazed plate warmness exchangers offer severa benefits that lead them to the great preference for space-saving solutions. Their compact layout, excessive heat transfer efficiency, lightweight construction, and durability cause them to perfect for a huge variety of packages, from HVAC and refrigeration systems to renewable power and business processing.

For industries and organizations looking to maximize overall performance whilst minimizing space and charges, brazed plate warmth exchangers provide the proper answer. Their capability to supply high performance in a compact, durable, and energy-efficient package deal guarantees that they’ll stay a famous choice for years yet to come.

As space will become an an increasing number of precious commodity in cutting-edge systems, the demand for brazed plate warmness exchangers will best continue to grow, making them a key issue within the destiny of efficient heat transfer era.