Properly wiring pool and spa motors is crucial for the safety and efficiency of your aquatic systems. Whether you are a DIY enthusiast or a professional, understanding the correct wiring procedures can prevent accidents, enhance performance, and extend the lifespan of your equipment. This comprehensive guide will walk you through the essential steps and considerations for wiring pool and spa motors, ensuring you achieve optimal results.

Understanding Pool and Spa Motors

Types of Motors

Pool and spa motors come in various types, each designed to meet specific needs. The most common types include:

- Single-Speed Motors: These motors operate at one constant speed and are often the most affordable option. They are simple to install and maintain but can be less energy-efficient compared to other types.

- Dual-Speed Motors: These motors offer two speed settings, allowing for more flexibility and energy savings. They are ideal for pools and spas that require different flow rates for various functions.

- Variable-Speed Motors: The most advanced and energy-efficient option, variable-speed motors can adjust to any speed setting, providing maximum efficiency and performance. They are more expensive but can significantly reduce energy costs over time.

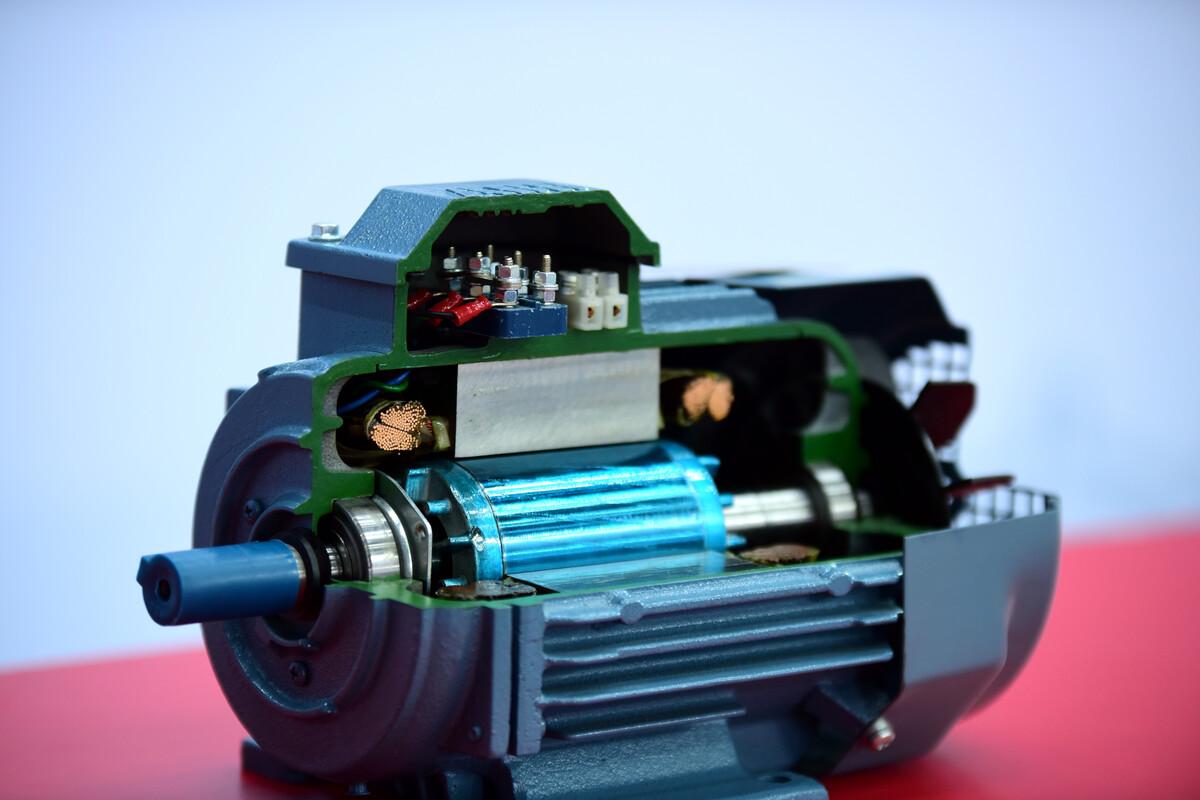

Components

Understanding the main components of pool and spa motors can help you troubleshoot issues and ensure proper installation. Key components include:

- Windings: Coils of wire that generate a magnetic field when an electric current passes through, causing the motor to rotate.

- Bearings: Support the motor shaft, allowing it to spin smoothly.

- Capacitors: Store and release electrical energy to help start and run the motor efficiently.

Functionality

In a pool or spa, motors drive the pumps that circulate water through filtration and heating systems, keeping the water clean and the water temperature at the desired level. Proper wiring ensures the motors function correctly, ensuring overall health and enjoyment.

Safety Precautions

Importance of Safety

It is important to prioritize safety during the wiring process to avoid electrical shocks, fires, and damage to equipment.

Safety Gear

Before starting any wiring project, gather the necessary safety equipment:

- Insulated gloves

- Safety goggles

- Insulated tools

Local Codes and Regulations

Always check local building codes and regulations before beginning any electrical work. These codes ensure your installation meets safety standards and may require a permit or inspection.

Professional Help

Even though this article tries to give detailed instructions, you may need to hire a professional for some activities. It is best to seek advice from a certified electrician if you are unclear about any procedure.

Tools and Materials Needed

Tools

Ensure you have the following tools on hand:

- Wire strippers

- Voltage tester

- Screwdriver

- Pliers

- Multimeter

Materials

You will need the following materials:

- Wires (appropriate gauge for your motor)

- Connectors

- Circuit breakers

- Electrical tape

- Grounding wire

Preparing for Installation

Power Supply

Verify that your power supply matches the requirements of your motor. Most pool and spa motors operate on 120V or 240V. Ensure the power supply can handle the motor’s load to prevent overloading and potential hazards.

Circuit Breaker

To prevent overloads and short circuits, you should choose a circuit breaker that matches the amperage rating of your motor.

Grounding

Ensure your motor is properly grounded according to the manufacturer’s instructions. Grounding wires direct excess electricity away from the motor, reducing the risk of electric shock.

Step-by-Step Wiring Guide

Turn Off Power

Before beginning any wiring work, turn off the power at the main panel to prevent electric shock. Use a voltage tester to confirm that the power is off.

Access Motor Terminals

Remove the motor’s access panel to reveal the wiring terminals. This panel is usually located at the back or side of the motor.

Wiring Connections

Follow these steps to connect the wires to the motor terminals:

Single-Speed Motors

- Identify Wires: Locate the power, ground, and neutral wires.

- Connect Power Wire: Attach the power wire to the designated terminal on the motor.

- Connect Neutral Wire: Attach the neutral wire to the corresponding terminal.

- Ground Wire: Connect the ground wire to the grounding terminal.

Dual-Speed Motors

- Identify Wires: Locate the high-speed, low-speed, ground, and neutral wires.

- Connect High-Speed Wire: Attach the high-speed wire to the appropriate terminal.

- Connect Low-Speed Wire: Attach the low-speed wire to the corresponding terminal.

- Ground Wire: Connect the ground wire to the grounding terminal.

- Neutral Wire: Attach the neutral wire to the designated terminal.

Variable-Speed Motors

- Identify Wires: Locate the variable-speed control, power, ground, and neutral wires.

- Connect Control Wire: Attach the control wire to the designated terminal for speed settings.

- Connect Power Wire: Attach the power wire to the corresponding terminal.

- Ground Wire: Connect the ground wire to the grounding terminal.

- Neutral Wire: Attach the neutral wire to the designated terminal.

Secure Connections

Ensure all connections are tight and secure. Use electrical tape to insulate exposed wires and prevent short circuits.

Reconnect Power

After completing the wiring connections, replace the motor’s access panel and restore power at the main panel. Test the motor to ensure it operates correctly.

Troubleshooting Common Issues

No Power

If the motor does not start, check the following:

- Ensure the power supply is on.

- Verify that the circuit breaker is not tripped.

- Check all wiring connections for tightness and proper placement.

Overheating

If the motor overheats, consider these potential causes:

- Insufficient ventilation around the motor.

- Incorrect voltage supply.

- Worn bearings or other internal components.

Noise

Unusual noises may indicate:

- Loose components.

- Worn bearings.

- Debris inside the motor.

Maintenance Tips

Regular Inspections

Perform routine checks on your motor to ensure all wiring connections remain secure and intact. Look for signs of wear or damage.

Cleaning

Keep the motor clean and free from debris. Dust and dirt can cause overheating and reduce efficiency.

Lubrication

Proper lubrication of the motor’s moving parts can extend its lifespan and improve performance. Follow the manufacturer’s recommendations for lubrication intervals and types.

Conclusion

Properly wiring pool and spa motors is essential for ensuring safe and efficient operation. By following this comprehensive guide, you can confidently wire your motor and maintain your pool or spa’s functionality. Remember to prioritize safety, follow local codes, and seek professional help from emergency industrial electricians if needed. With the right knowledge and tools, you can enjoy a well-maintained and enjoyable aquatic experience.