Injection molding, the process of shaping molten plastic into intricate designs, has revolutionized manufacturing. From the intricate gears in your watch to the sturdy shell of your phone, countless everyday products owe their existence to this remarkable technology. But navigating the world of injection molding companies can be daunting, especially for first-timers. This guide empowers you with the knowledge to make informed decisions and partner with the perfect injection molding company for your project.

Unveiling the Power of Injection Molding

Injection molding boasts several advantages that have cemented its place as a cornerstone of modern manufacturing:

- Mass Production: Injection molding excels at producing large quantities of identical parts efficiently and consistently, making it ideal for high-volume applications.

- Design Flexibility: The technology allows for intricate shapes and complex features, pushing the boundaries of product design.

- Material Versatility: A wide range of plastic materials can be used, each offering unique properties to cater to specific needs.

- Cost-Effectiveness: For high-volume production runs, injection molding offers significant cost savings compared to alternative manufacturing methods.

- Durability and Precision: Injection molded parts are known for their strength, dimensional accuracy, and consistent quality.

Demystifying the Injection Molding Process

The injection molding process itself can be broken down into several key steps:

- Mold Design: A critical initial step, the mold design translates your desired product into a detailed blueprint for the mold cavity.

- Mold Manufacturing: Using specialized techniques like CNC machining, the mold is meticulously crafted from high-grade steel.

- Material Selection: The ideal plastic material is chosen based on the product’s specific requirements like strength, flexibility, and heat resistance.

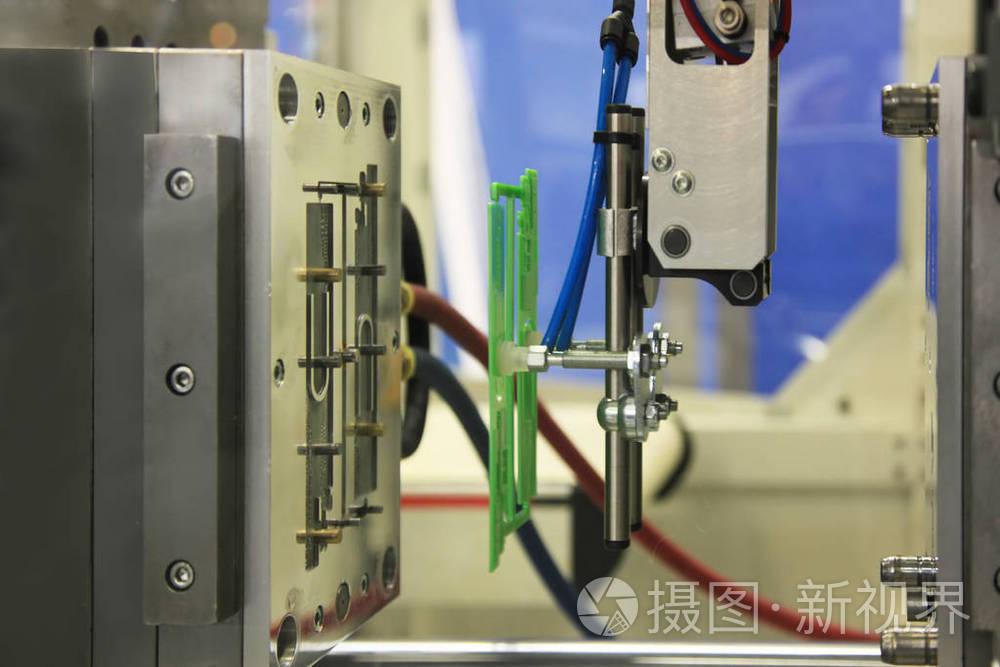

- Injection Process: Plastic pellets are melted and injected into the mold cavity under high pressure, filling every intricate detail.

- Cooling and Ejection: The plastic cools and solidifies within the mold, and the finished part is ejected.

- Secondary Operations: Additional processes like trimming, finishing, or assembly might be employed to achieve the final product.

Finding the Right Fit: Key Considerations for Choosing an Injection Molding Company

Selecting the right injection molding company is crucial for the success of your project. Here are some key factors to consider:

- Experience and Expertise: Look for a company with a proven track record and extensive experience in your specific industry or with similar products.

- Technology and Capabilities: Ensure the company possesses the necessary technology and equipment to handle your project’s complexity and desired volume.

- Quality Control: Prioritize companies with a robust quality control system to guarantee consistent, high-quality parts.

- Communication and Customer Service: Effective communication and a commitment to understanding your needs are essential for a smooth and successful partnership.

- Cost and Pricing: While cost is a factor, prioritize value over the cheapest option. Look for a company that offers competitive pricing while delivering exceptional quality.

Pro Tip: Consider location as well. Finding a reputable injection molding company close by injection molding near me can facilitate easier communication and project oversight.

Beyond the Basics: Additional Considerations

Here are some additional factors to keep in mind when choosing an injection molding company:

- Project Complexity: For highly complex projects, partnering with a company specializing in intricate designs might be beneficial.

- Intellectual Property Protection: Ensure the company has robust measures in place to safeguard your intellectual property rights.

- Sustainability: If environmental responsibility is a priority, inquire about the company’s sustainability practices and use of recycled materials.

Exploring Your Options: A Glimpse into the Global Landscape

The world of injection molding companies encompasses a vast array of players, from established giants to niche specialists. Depending on your project’s needs, you might consider:

- Domestic Injection Molding Companies: Partnering with a domestic company can offer advantages like easier communication and potentially faster turnaround times.

- Offshore Injection Molding Companies (China): China is a major player in injection molding, offering competitive prices. However, thorough research and due diligence are crucial when considering China injection molds.

Building a Successful Partnership: Communication is Key (continued)

- Desired part specifications: Dimensions, tolerances, material preferences, and any specific functionalities.

- Production volume: The number of parts you require and potential future production needs.

- Timeline: Your desired timeframe for mold development and production.

- Budget: A realistic budget for the project, including mold development and part production.

By fostering open communication, you can establish a strong foundation for collaboration and ensure the injection molding company fully understands your vision.

Understanding the Costs Involved

Injection molding costs can be broken down into two main categories:

- Mold Development Costs: This includes the engineering design, mold tooling, and initial mold trials. Mold development costs are typically a one-time expense.

- Part Production Costs: This refers to the per-unit cost of producing your plastic parts. Factors like material choice, complexity, and volume influence this cost.

It’s essential to get clear quotes from potential companies that detail both mold development and part production costs. This transparency helps you make informed decisions and avoid budget surprises.

The Power of Negotiation

Once you’ve received quotes from various injection molding companies, don’t be afraid to negotiate. Here are some aspects you might consider:

- Volume Discounts: For larger production runs, negotiate for a lower per-unit cost.

- Payment Terms: Discuss payment schedules and potential milestone-based payments to manage cash flow.

- Mold Ownership: Negotiate who owns the mold after development. Owning the mold gives you more control over future production with other companies.

Remember, negotiation is a two-way street. Be prepared to justify your requests and demonstrate your commitment to a successful partnership.

Embracing Innovation: The Future of Injection Molding

The injection molding industry is constantly evolving, embracing new technologies and advancements. Here are some exciting trends to watch:

- Additive Manufacturing Integration: The integration of 3D printing technologies with injection allows for faster prototyping and potentially complex mold designs.

- Sustainable Practices: The use of recycled materials and energy-efficient processes are gaining traction as companies prioritize environmental responsibility.

- Advanced Automation and Robotics: Injection molding is increasingly automated, improving efficiency and consistency while minimizing human error.

These advancements are shaping the future of injection molding, offering exciting possibilities for even more complex, high-quality, and sustainable production.

Conclusion: The Path to Injection Molding Success

By understanding the process, key considerations, and the landscape of companies, you’re well-equipped to embark on your manufacturing journey. Remember, choosing the right partner is crucial. Prioritize companies that possess the skills, capabilities, and commitment to quality that align with your project’s needs. With a clear vision, open communication, and a dash of negotiation, you can forge a successful partnership and leverage the power of injection molding to bring your product ideas to life.