In the world of automation and robotics, the precise control of motion is crucial. Among the key components that facilitate this control are actuators, which convert energy into motion. There are two primary types of actuators used in various applications across industries: linear actuators and rotary actuators. Understanding the differences between these two can help engineers and designers choose the right motion solution for their specific needs.

What Are Linear Actuators?

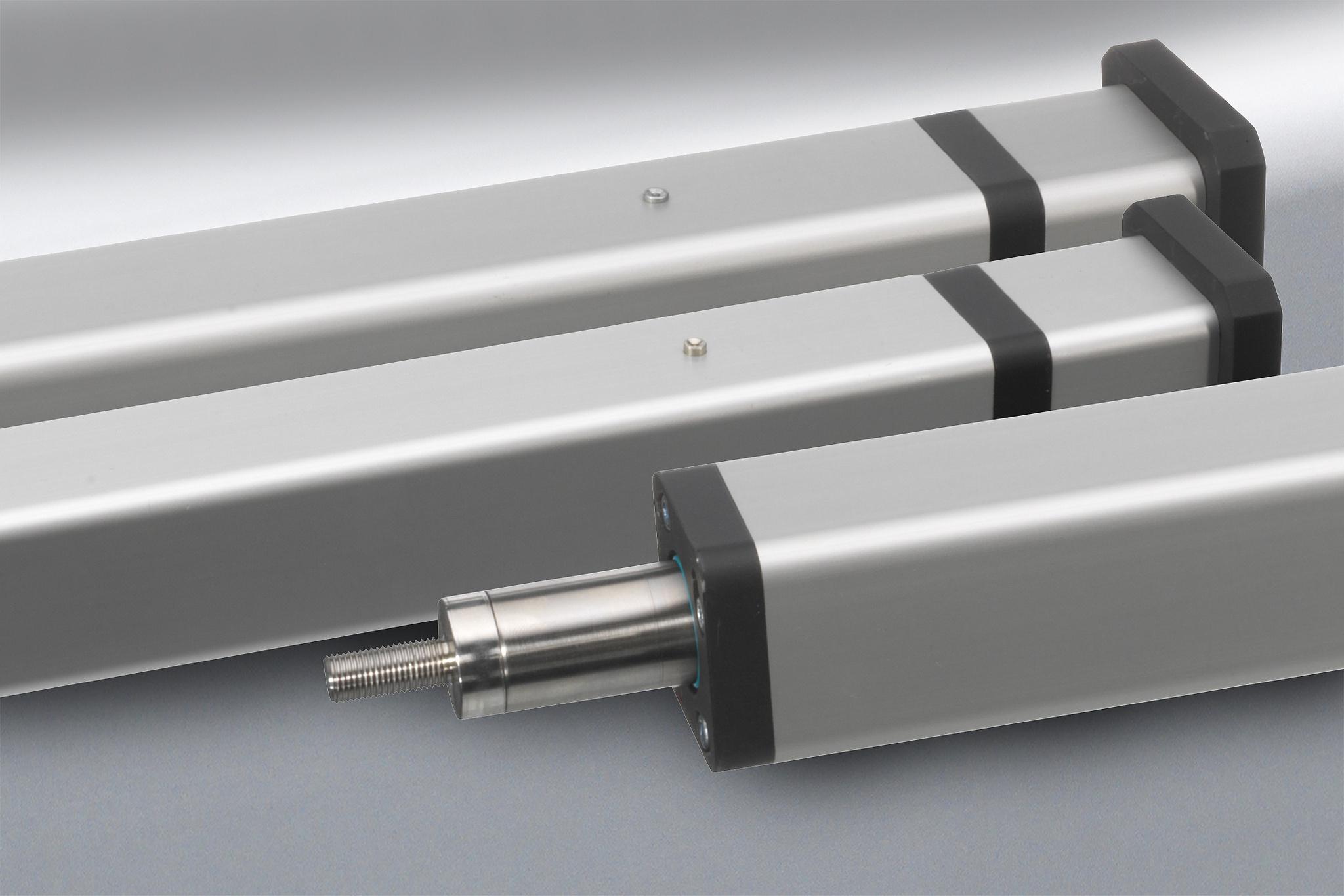

Linear actuators create motion in a straight line and are used in everything from adjustable desks to complex robotics. They are particularly valued for their ability to provide precise positioning along a single axis. This capability makes them indispensable in applications where precise, controlled linear displacement is required.

What Are Rotary Actuators?

In contrast, rotary actuators produce rotational motion and are essential in applications where angular displacement is needed. They are commonly found in robotics, manufacturing automation, and vehicle steering systems. Rotary actuators allow for the rotation of components with high torque, making them ideal for tasks that involve turning or swiveling.

Key Differences Between Linear and Rotary Actuators

- Mechanism of Action

The fundamental difference between linear and rotary actuators lies in their mechanism of action—linear versus rotational movement. Linear actuators extend and retract in a straight line, whereas rotary actuators rotate around an axis.

- Applications

The choice between a linear and a rotary actuator often depends on the application. For instance, linear actuators are preferred in factory automation for tasks like pushing or pulling a component along a conveyor, while rotary actuators are suited for tasks that require circular movement, such as robot joint control.

- Precision and Control

Both types of actuators can be designed to offer high precision and control, but the nature of their motion can influence their effectiveness in different scenarios. Linear actuators provide direct in-line force, which can be easier to control with high accuracy. Rotary actuators, however, offer a rotational force and may require additional components to achieve the same level of precision as linear actuators in certain applications.

Choosing the Right Actuator

When selecting an actuator, consider the following factors to determine the most suitable type for your project:

- Motion Requirements

Assess the type of motion required by your application. Does it need straight-line movement, rotational movement, or a combination of both? For purely linear movements, linear actuators are typically the best choice. For rotational or turning movements, rotary actuators are more appropriate.

- Load and Speed

Evaluate the load and speed requirements of your application. Linear actuators are excellent for applications requiring high force and precision at slower speeds, whereas rotary actuators can generally handle higher-speed rotations with variable torque.

- Space Constraints

Space constraints can also influence the choice of actuator. Linear actuators often require more space to accommodate the length of travel, whereas rotary actuators usually have a more compact footprint due to their circular motion.

- Environmental Factors

Consider the environment in which the actuator will operate. Factors such as temperature, moisture, and exposure to dust can affect the performance and lifespan of an actuator. Some actuators are better suited to harsh environments than others, so selecting one that can withstand specific environmental conditions is crucial.

- Cost and Complexity

Finally, weigh the cost and complexity of installation. In general, linear actuators tend to be simpler to implement, as they do not require additional components to convert motion. Rotary actuators might need extra gearing or couplings, which can add to the cost and complexity.

Conclusion

ETI System, choosing between a linear and a rotary actuator is a decision that affects the efficiency, cost, and performance of your project. By understanding the fundamental differences and considering the specific requirements of your application, you can select the right type of actuator that provides the optimal motion solution. Whether it’s the straightforward push and pull of a linear actuator or the complex rotational movements of a rotary actuator, the proper choice will ensure your machinery operates at peak performance, contributing to the overall success of your operations.

In summary, while both linear actuators and rotary actuators play pivotal roles in modern automation and robotics, their distinct characteristics make them suitable for different applications. Assessing your specific motion needs carefully will help you make an informed decision, ensuring that your actuator not only meets but exceeds your expectations.